In our recent article, we touched on the basics of Smart Factory concept, its benefits and challenges that come with implementation. In a word, it’s all about the Internet of things, machine learning and advanced analytics that transform factories into dynamic, interconnected infrastructure. The “smartness” of the system generally refers to two things:

- meaningful real-time communication across the factory;

- dynamic transfer of data into business and operational intelligence.

That said, Smart factory goes beyond the traditional automation of processes and uses constant data stream to create fully connected and flexible system with the minimal amount of resources, allows systems to learn and adapt to changing requirements.

64% of CxOs from outperforming industrial products companies are reported by IBM to have already been investing in artificial intelligence and cognitive technologies for their factories. However, this stats don’t include mediocre manufacturing companies not mentioning small businesses who are reluctant to bring innovative technologies to their organization because of the high cost, security and operations efficiency concerns.

This article gives insight on how to make a path to smart and interconnected factory step by step.

Start small

The first question to ask is “Where to start?” You need a secure, comprehensive and well-designed solution that allows for being upgraded with new elements and third-party services and keeps the high level of performance all the way through. It will be a foundation for your Smart Factory. What does it consist of?

- Sensors and actuators installed in smart “things”. They collect data, transfer it to the cloud and make the machines perform the actions accordingly.

- Gateways process and filter collected data before it goes to the cloud as well as provides for secure data transmission.

- Data lake stores raw data which is then extracted and transmitted to the data warehouse.

- Big data warehouse stores processed data and contextual information in the cloud.

Starting small, testing single systems, and iterating with other ones, the solution is getting more manageable and ready to scale with additional items, lines, people and other assets, creating more value at every step of the way.

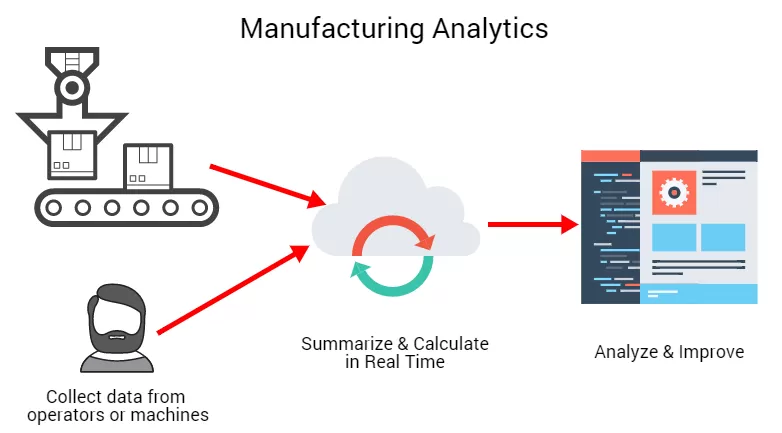

Proceed with analytics and visualization

Collected data itself is worth nothing without being analyzed and visualized. Once the basic network is set up, it’s time to move to the next level of maturity and analyze loads of generated information in sophisticated ways using data analytics tools. These tools deal with real-time data on what machines do or fail to do and historical data on performance. All this provide operations engineer with comprehensive actionable metrics to use it in decision-making and improve the production line.

Additionally, Smart Factories may employ AI, machine learning and cognitive computing that allow for interpreting data, building predictive maintenance models and adjusting systems to the data from connected things.

As the network of connected devices scale to the enterprise level, the data sets will expand and comprise more processes and use cases.

Monitor and optimize

Analyzed data can provide valuable insights on a production process and indicate whether it meets quality and operational standards. Overall, you get the insights on the overall equipment effectiveness, assembly faults, SPC and CPK charts. Process monitoring includes the statuses of each thing in the line, orders, and other parameters, which allows for setting up the automated workflows, increasing product quality and reducing cost.

What is more, Smart Factory is characterized by self-optimization that predict and detect causes of potential defects or poor quality and autonomously run production processes, alter traditional workflows and governance infrastructure.

As a result, the factory operation is optimized with minimal human intervention and high reliability.

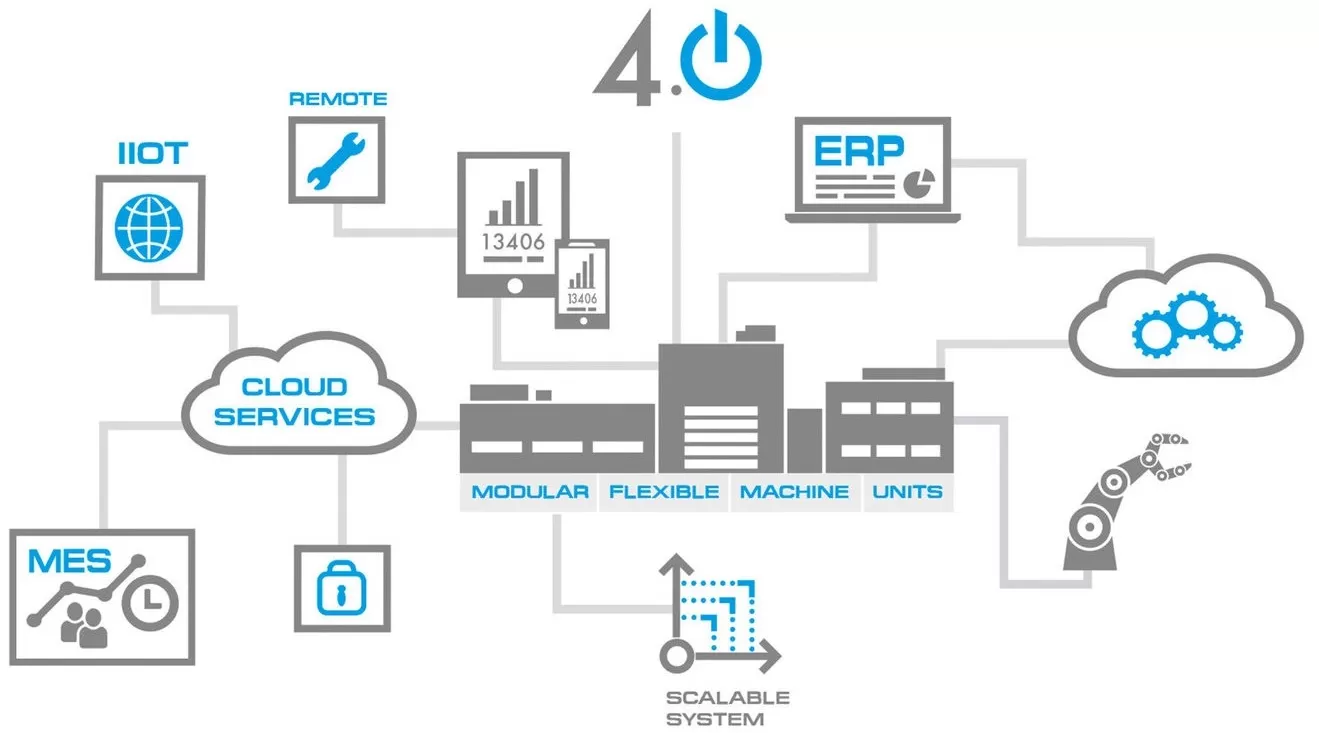

Grow network

Smart factory development is an ongoing process that requires network-growing approach. That said, the network should allow for further scaling and integration of new assets: “things”, sensors, data sources, and third-party systems into the system. What are the possible integrations in Smart Factory network? Look at these few examples:

- Voice recognition hands-free systems for factory workers and engineers.

- Intelligent ERP for process management.

- Data visualization and BI instruments for COO.

- Analytical tools for R&D departments.

- Field service management and other apps for on-the-go usage.

In this case, scalability means more than just adding new elements to the network but also their functional growth, asset synchronization, improved and automated workflow, and optimized resource consumption. Network optimization leads to significant cost reduction, effective waste management, shorter downtime, higher product quality, and, as a result, more satisfied customer.

A bottom line is this

To leverage the full potential of the Smart Factory, you’ll need to create an interconnected infrastructure and integrate your enterprise asset management with IoT, analytics and cognitive to manage and process all factory’s processes in real time. These solutions will contribute to the added value for the company and its customers allowing for the creation of the on-demand production and change the manufacturing world.

For more information about software technologies and methodologies to enable Smart Factory, reach out to our IT consultant in a live chat and get free consultancy.