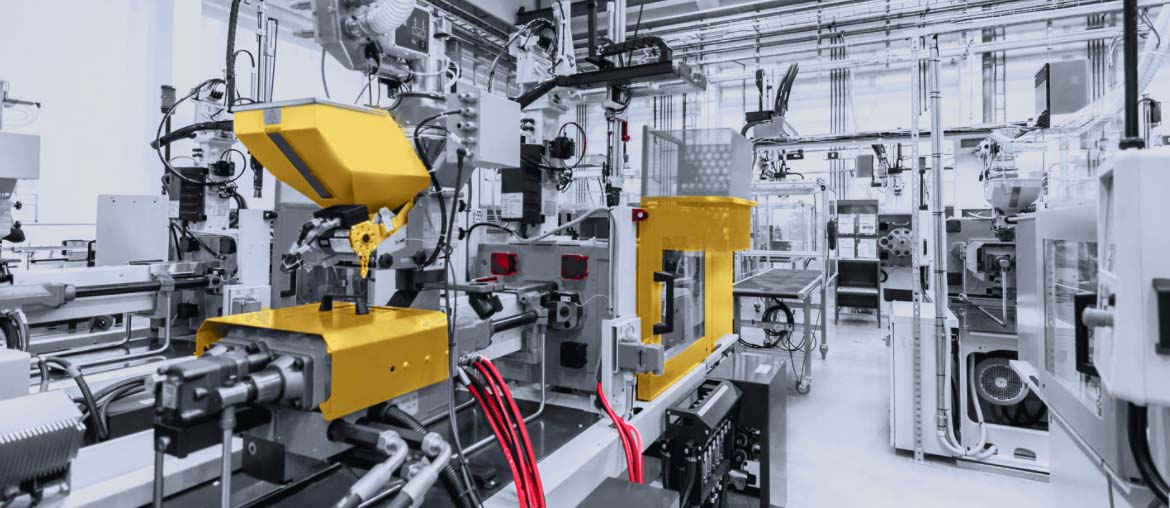

Predictive Maintenance Software

Development Services

Sustainability and ESG Services for the Manufacturing Industry

Sustainability and ESG services are a data-driven approach to reducing environmental impact through predictive maintenance systems. The service is for companies using equipment monitoring and forecasting technologies. The result is lower energy use, fewer failures, and ESG optimization. Elinext integrates ESG analytics into predictive maintenance solutions.

Get Comprehensive Predictive

Maintenance Services

-

Data And Signal Processing

We collect and process real-time data from equipment sensors, ensuring high-quality, noise-free input for accurate predictive analysis and early detection of potential failures.

-

Condition Monitoring And Diagnosis

Our solutions enable continuous condition monitoring and advanced diagnostics to detect anomalies, track asset health, and schedule timely maintenance before costly breakdowns occur.

-

Predictive Ability Services

Among our predictive maintenance services is predictive models development. These models analyze historical and real-time data to forecast potential equipment failures, helping businesses reduce unplanned downtime and maintenance costs.

-

Decision Support Services

Elinext offers intelligent decision support tools that help maintenance teams prioritize actions, optimize resource allocation, and create data-driven maintenance schedules.

-

Requirement Analysis & Consulting

Our experts analyze your operational needs and offer consulting and predictive maintenance services to design the most effective predictive maintenance strategies tailored to your industry and business model.

-

We build custom predictive maintenance software that aligns perfectly with your business processes, ensuring seamless workflows, maximum system flexibility, and easy scalability.

-

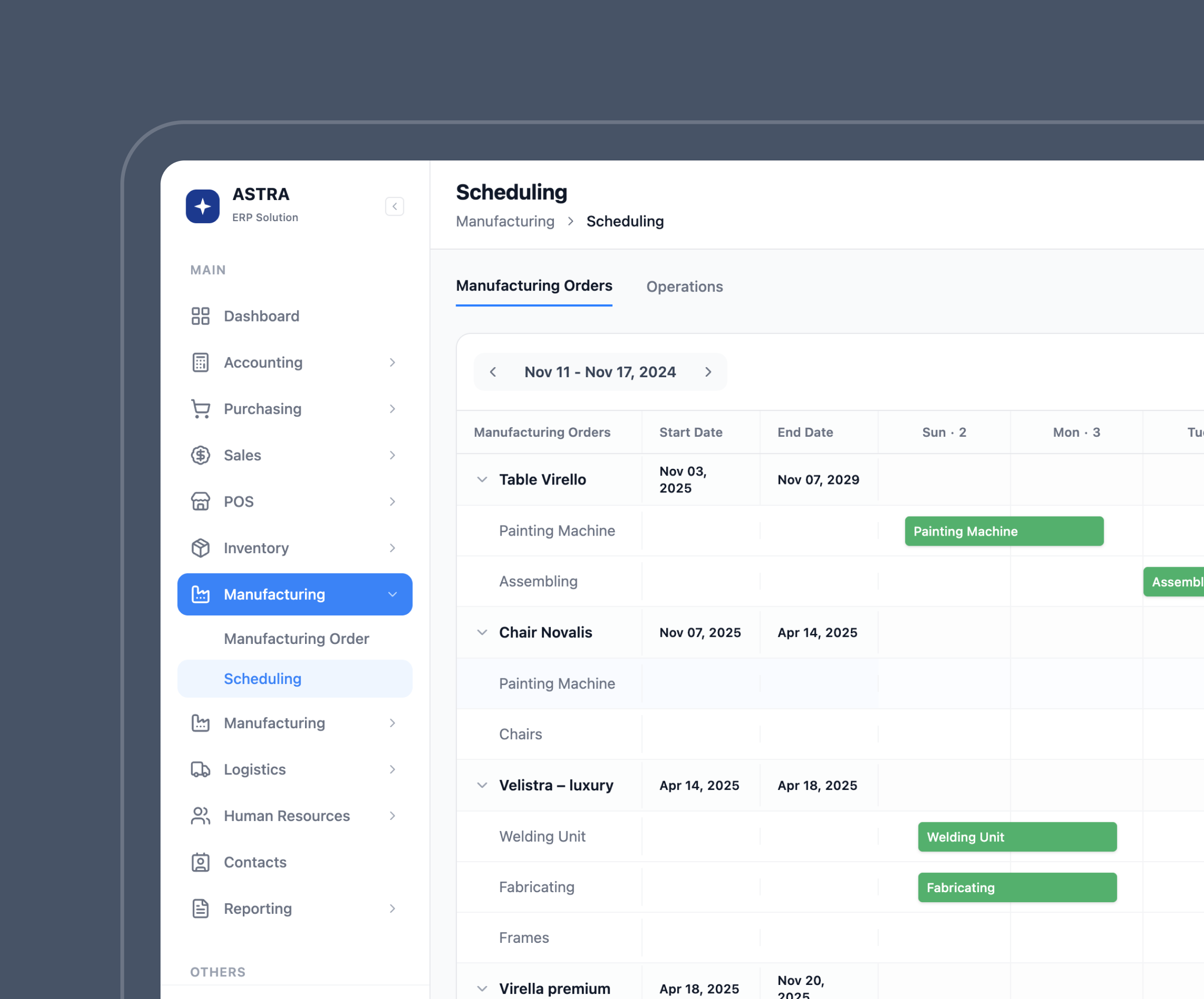

Integration With Existing Systems

Elinext as one of its predictive maintenance services ensures smooth integration of such solutions with your existing ERP, CMMS, and IoT platforms, providing a unified ecosystem for streamlined operations.

-

We integrate IoT sensors and edge devices into predictive maintenance systems, enabling real-time data collection, local analysis, and faster response times with reduced network loads.

-

Our team designs and trains AI/ML models that accurately predict asset failures, improve diagnostic precision, and evolve over time to deliver even higher prediction accuracy.

-

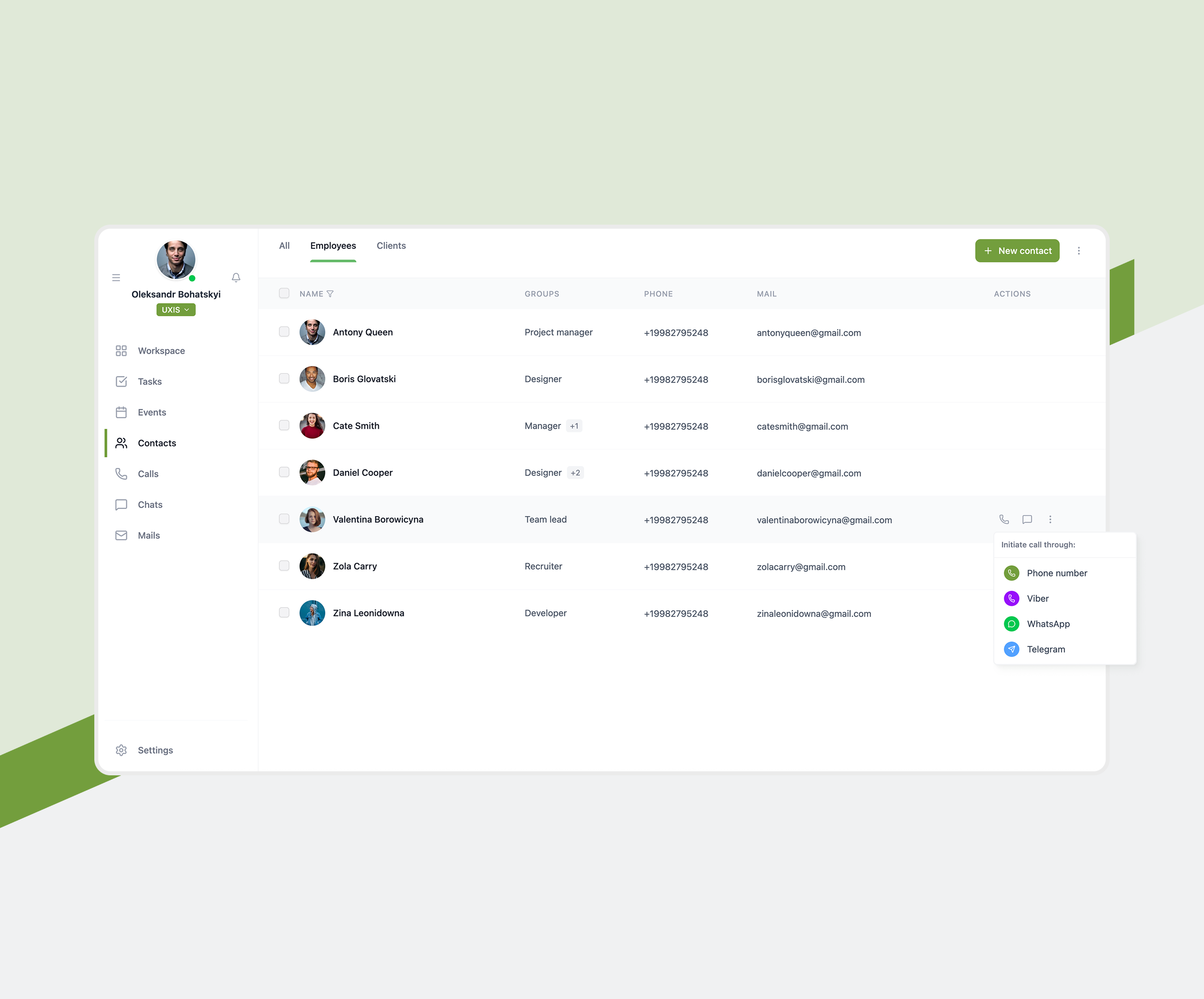

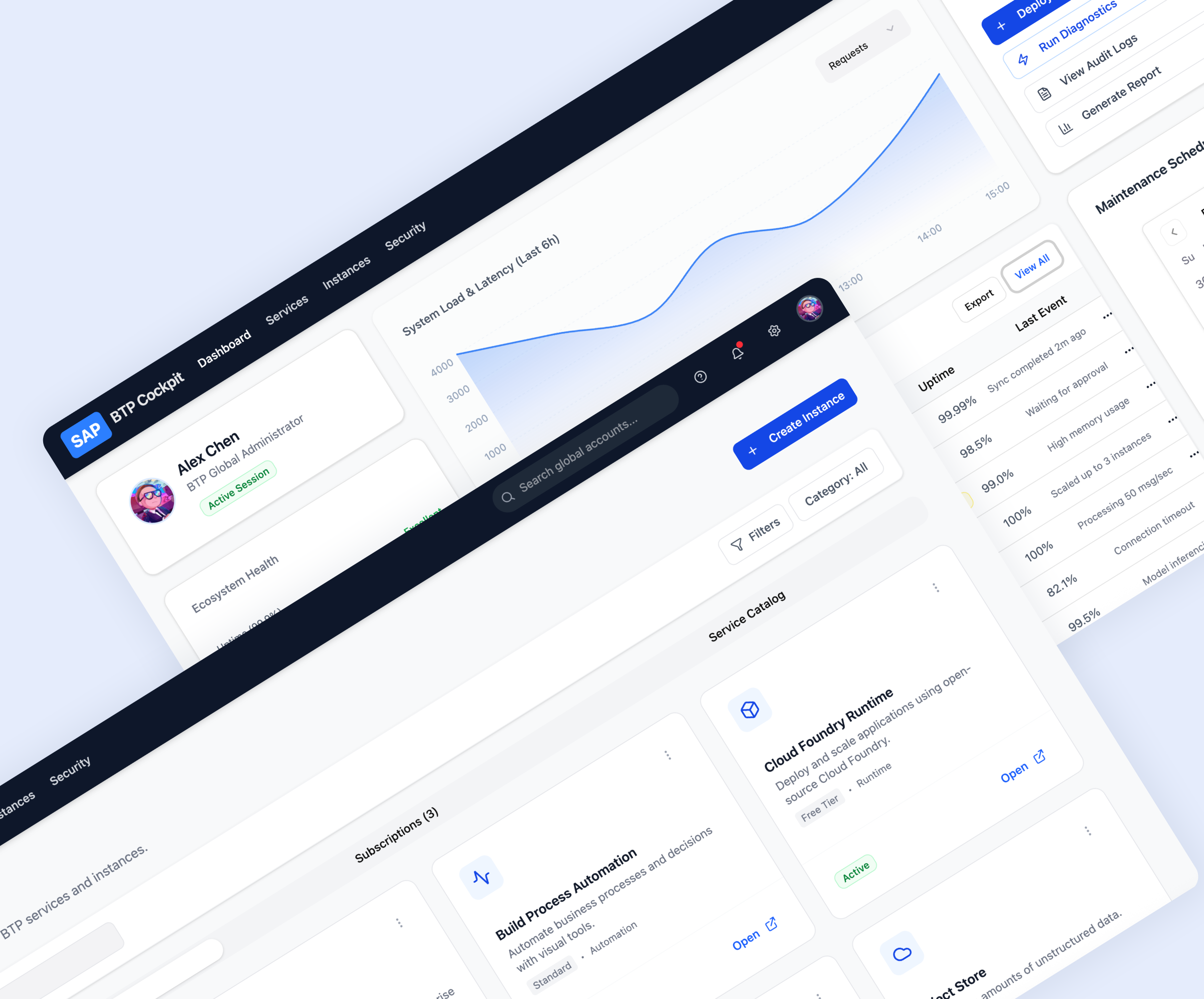

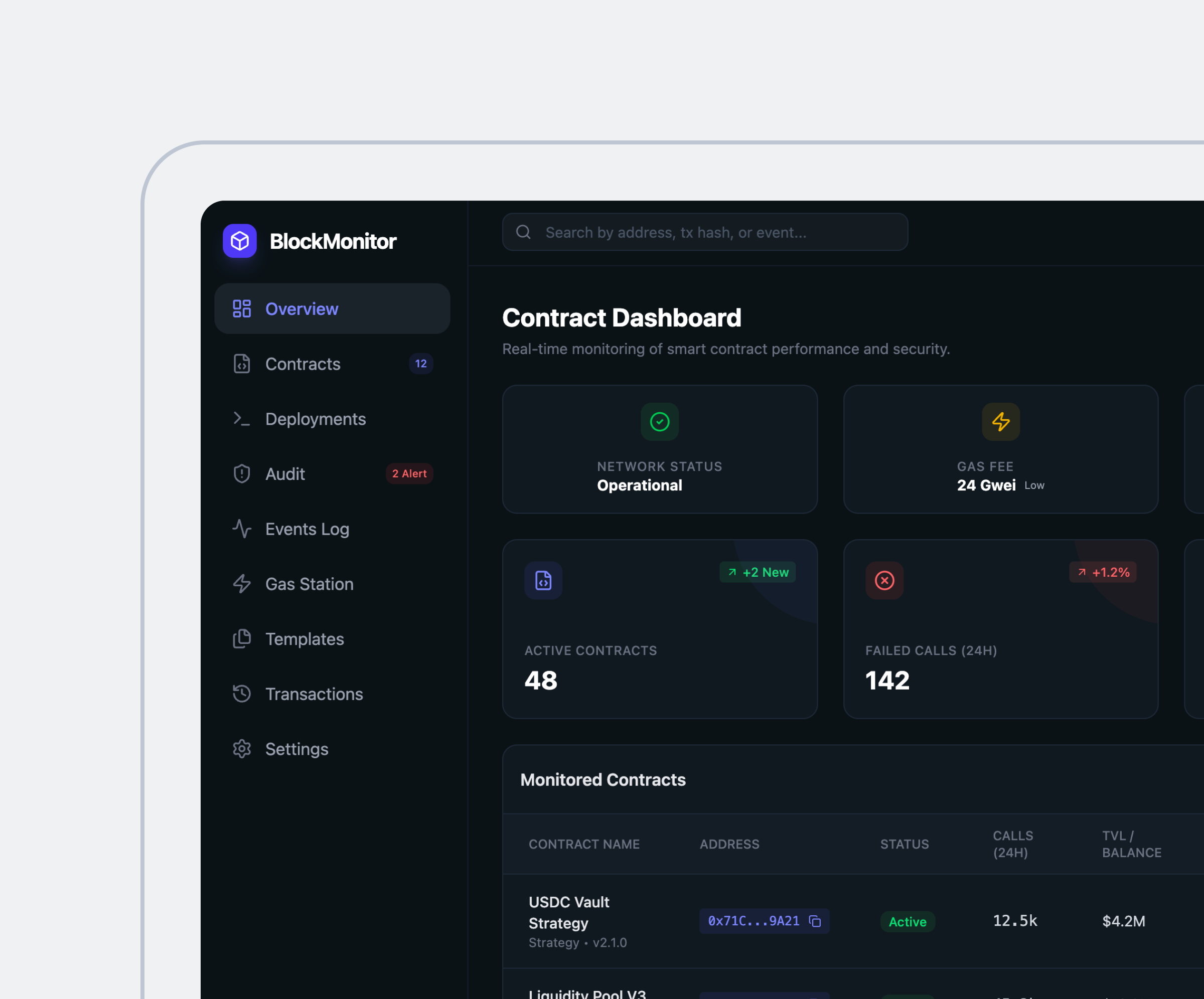

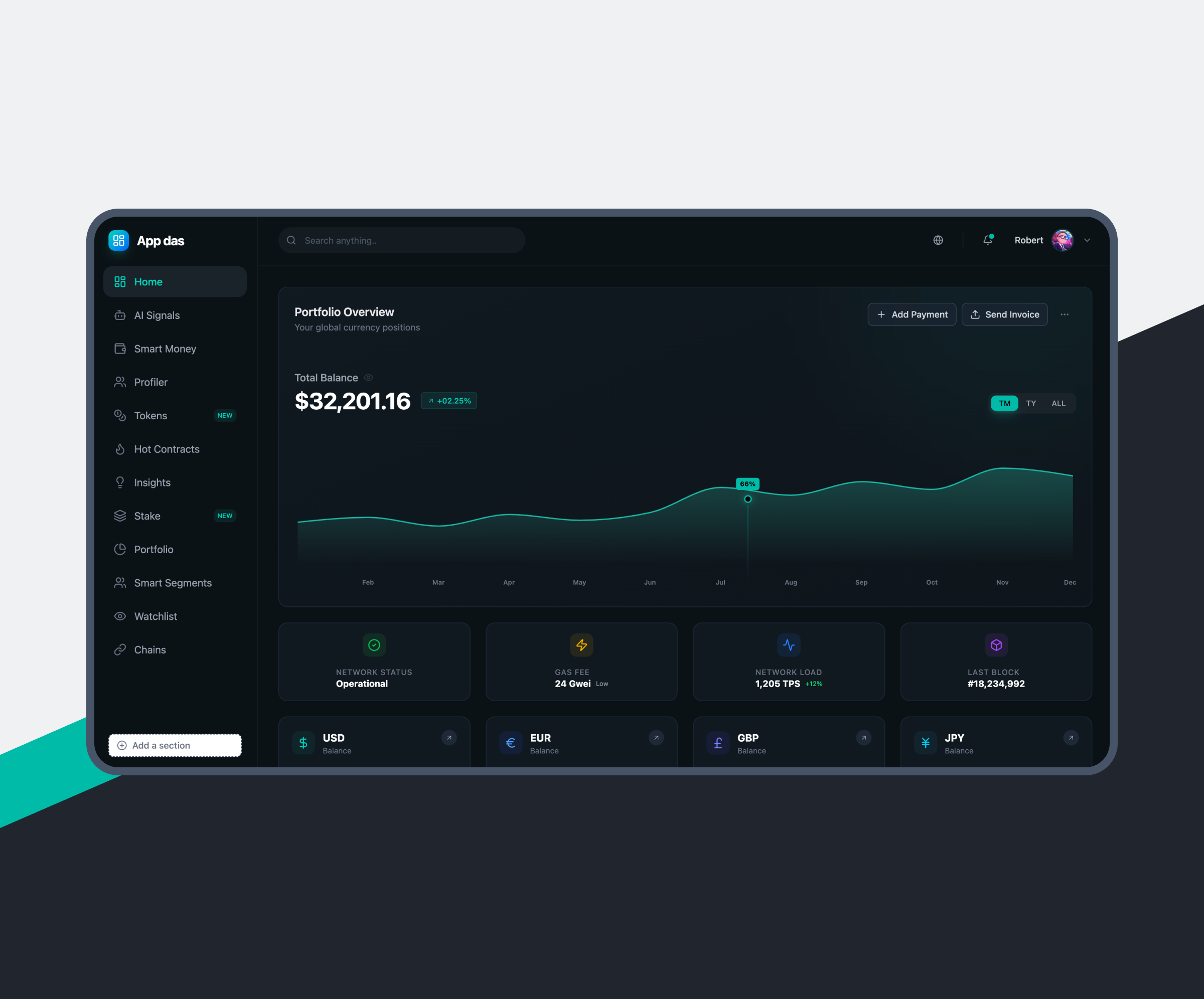

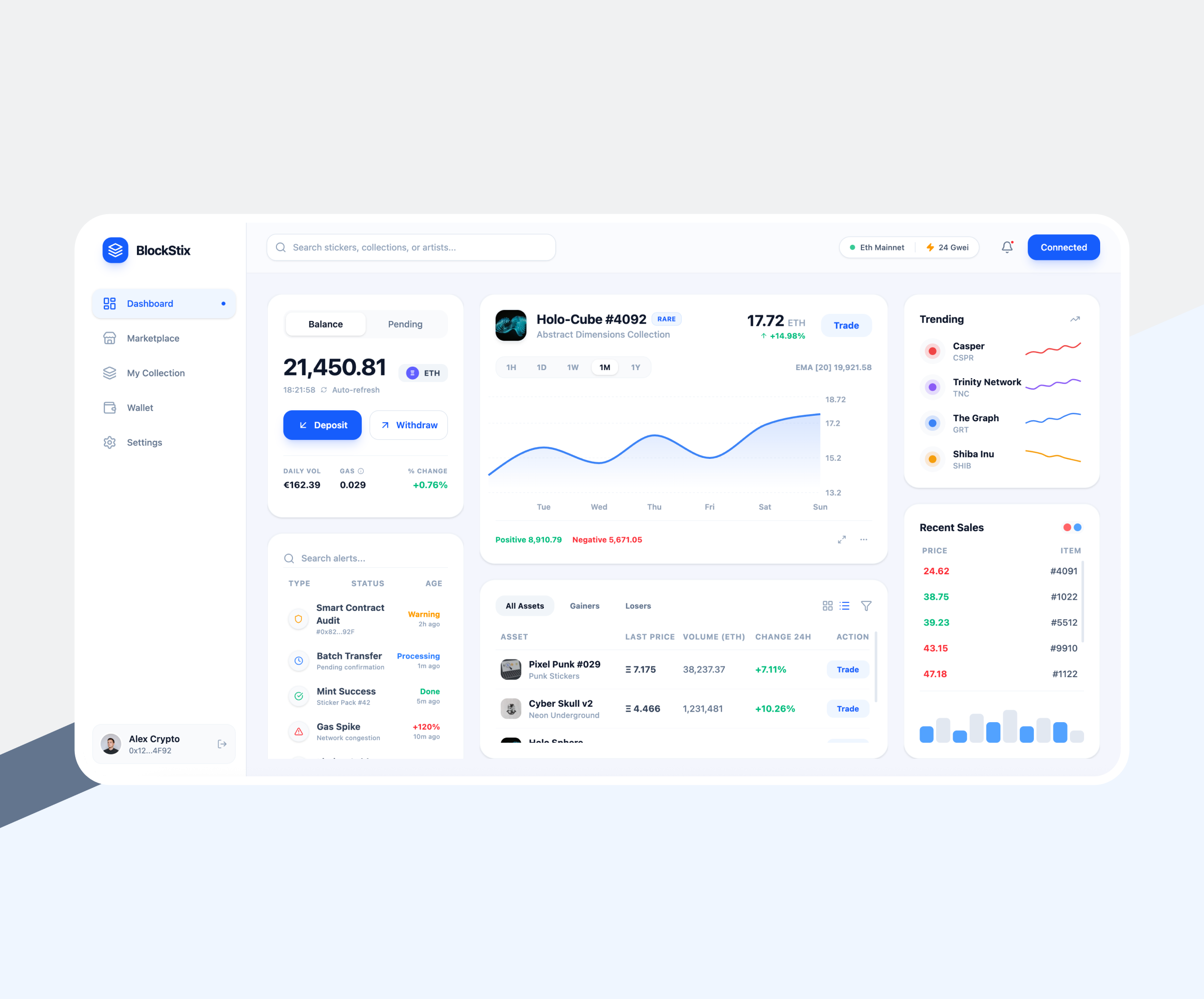

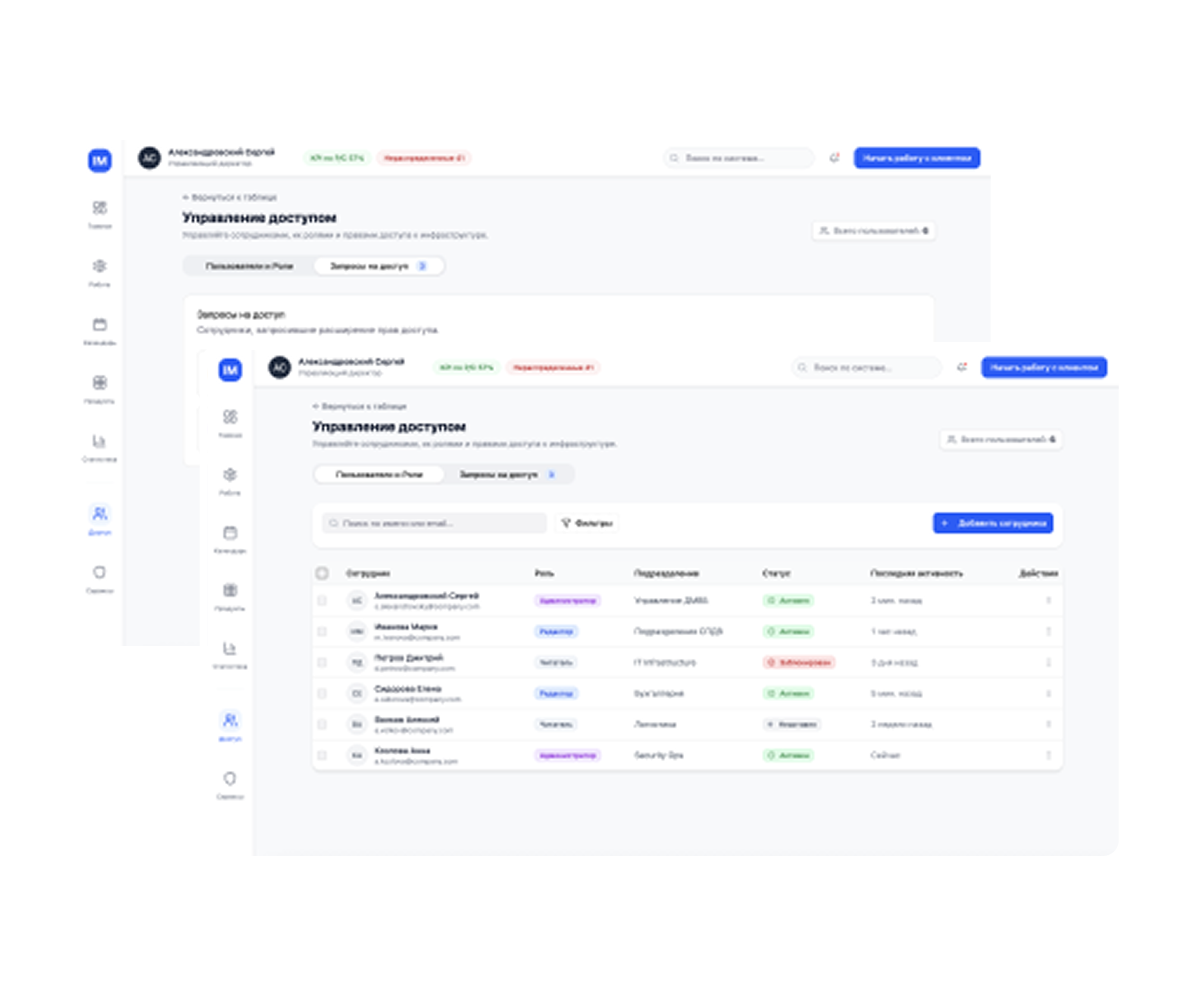

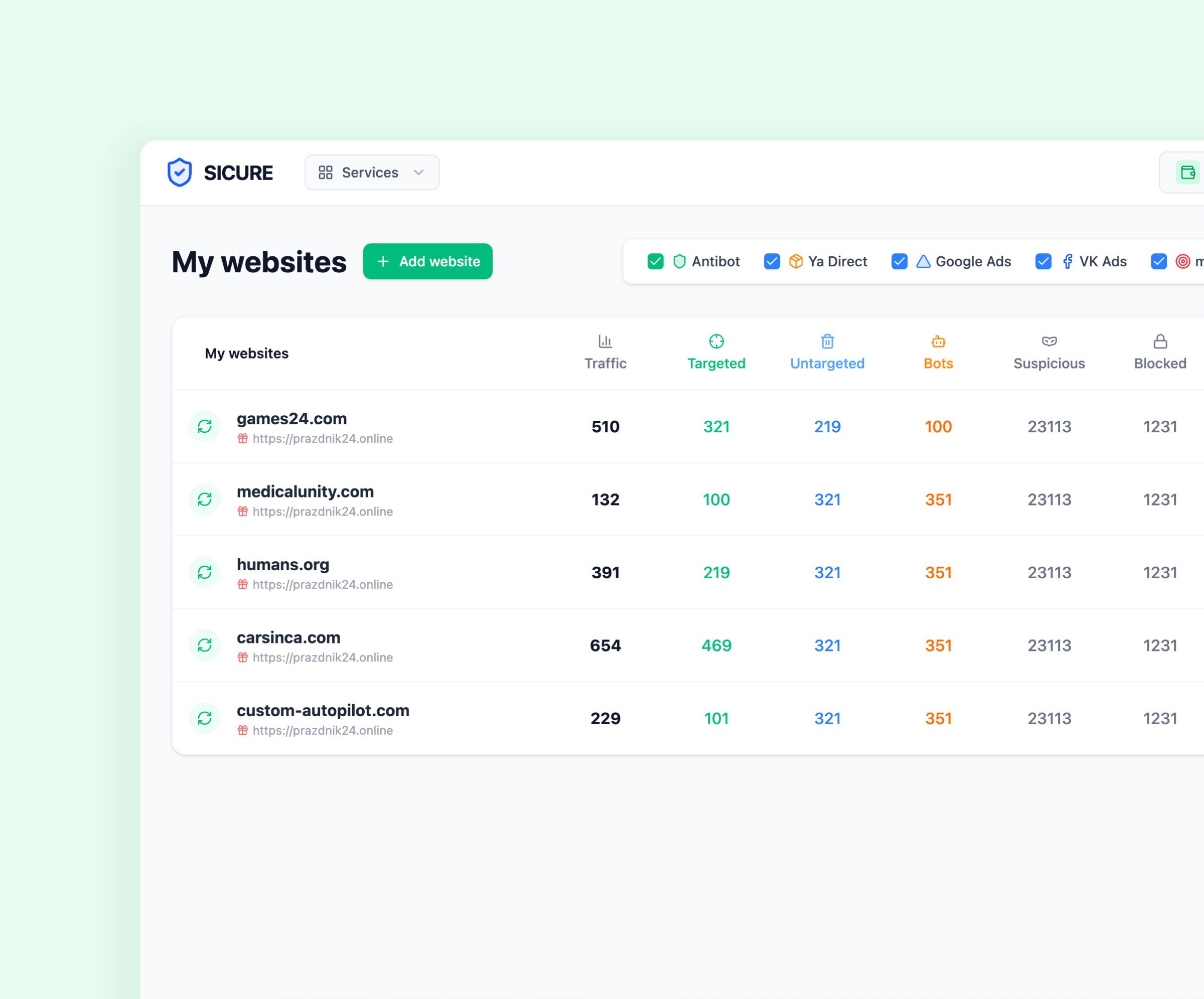

Dashboard And Analytics Visualization

We create intuitive dashboards and visual analytics tools that display asset conditions, KPIs, and predictive insights, making critical information easily accessible for quick decisions.

-

Predictive maintenance services by Elinest include flexible deployment options, whether in the cloud or on-premises, ensuring secure access, scalability, and continuous support based on your specific IT infrastructure.

-

Post-Deployment Support And Model Optimization

Our job doesn’t end at deployment. We provide predictive maintenance software development services that include continuous model optimization, performance monitoring, and system updates to ensure your predictive maintenance solution evolves with your business.

Our Awards and Recognitions

Industries We Serve

Core Technologies We Work with

-

Programming languages 12+0Practice20 yearsProjects130+Workforce50+Popular programming language enabling enterprises to build AI, analytics, web, and backend apps with simplicity and scalability globally.Practice27 yearsProjects250+Workforce60+Enterprise programming language enabling enterprises to build scalable, reliable, and secure applications globally.Practice20 yearsProjects150+Workforce50+Microsoft’s cross-platform framework enabling enterprises to build scalable apps for desktop, mobile, and web globally.Practice13 yearsProjects100+Workforce50+JavaScript runtime enabling enterprises to build scalable, fast, and real-time applications globally.

-

-

Data analytics 12+0

-

-

ML frameworks 12+0

-

-

Databases 12+0

-

What Our Experts SayWhat Our Experts Say

The Benefits Of Predictive Maintenance

Software Development Solutions By Elinext

Choose Your

Service Option

Hire Dedicated Team

from Elinext

Why Elinext?

Listen to Our Clients

Looking for Related Services?

FAQ

-

Predictive maintenance software analyzes real-time and historical data to predict equipment failures, helping businesses reduce downtime and optimize maintenance schedules.

-

Yes, our predictive maintenance company seamlessly integrates solutions with your current ERP, CMMS, IoT, and SCADA systems to create a unified, efficient ecosystem.

-

Development time usually ranges from four months to a year, and beyond, depending on system complexity, the number of integrations, and the specific requirements of your project.

-

As a decent experienced predictive maintenance company, we utilize all the precautions. We apply encryption, role-based access control, secure APIs, and regular security audits to ensure the protection of all operational and sensor data.

-

The cost oа delivering predictive maintenance software development services varies depending on project size, data complexity, and feature scope. We offer customized quotes after analyzing your specific business needs.

Predictive Maintenance Software Development

ArticlesPredictive Maintenance Software Development

Articles

Articles

Articles