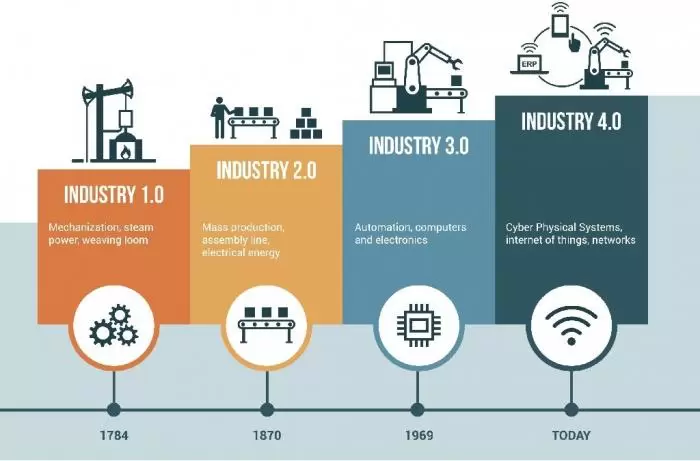

In the last decade, the adoption of the Internet of things on the enterprise level has risen to the global scale. The first country to claim the new industrial revolution is Germany who announced the term “Industrie 4.0” at the famous Hannover Fair back in 2011. Now, the concept of smart manufacturing has shaken off the hype and got real. That’s why we think it’s time to shed light on the Industrial Internet of Things, or IIoT, and estimate its perspectives in the nearest future.

What is smart manufacturing?

The whole idea of a Smart Factory is based on the Internet of Things, which links the embedded computational elements, sensors and actuators to digital networks and allows for processing the data from connected devices. Each of these embedded systems in the factory is assigned with the IP-addresses to be monitored online. Being automated and self-sufficient, this kind of value chain encourages decentralization of process control and lies at the root of Industry 4.0.

That said, implementation of the smart factory for manufacturing businesses leverages the automation of processes with less human intervention, the flexibility that allows for early system failure detection, and system automation.

So, what software solutions do you need to enable the Industrial Internet of Things?

- Embedded – it helps devices to interact with the Internet and transmit information via the gateway.

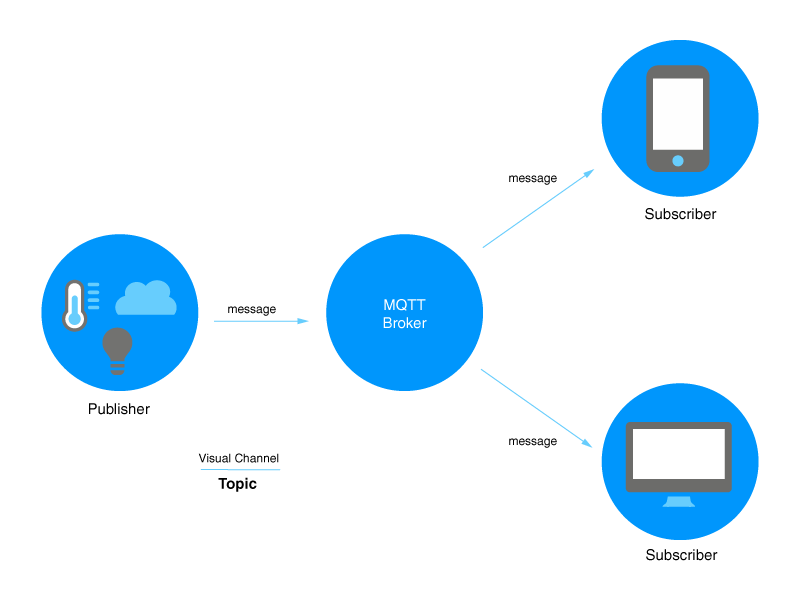

- Backend – it should communicate with multiple devices, clients, and microservices, allow for seamless integrations and high level of connectivity. The technologies depend on the specific project, however, mind the protocols that fit specifically to IIoT infrastructures, such as MQTT or CoAP.

- Frontend – UX and UI development and design should cover the use case of third-party integrations with BOM, CRM, ERP and other software and be responsive in real time

- Data Science – The system should be able to process high volumes of data in real time and provide actionable predictive analytics with AI&ML tools.

Creating a robust infrastructure for Smart Factory may seem burdensome, but the result is worth effort. All you need is an industrial software development team with the right skill set and a lot of testing.

IoT versus M2M on the enterprise

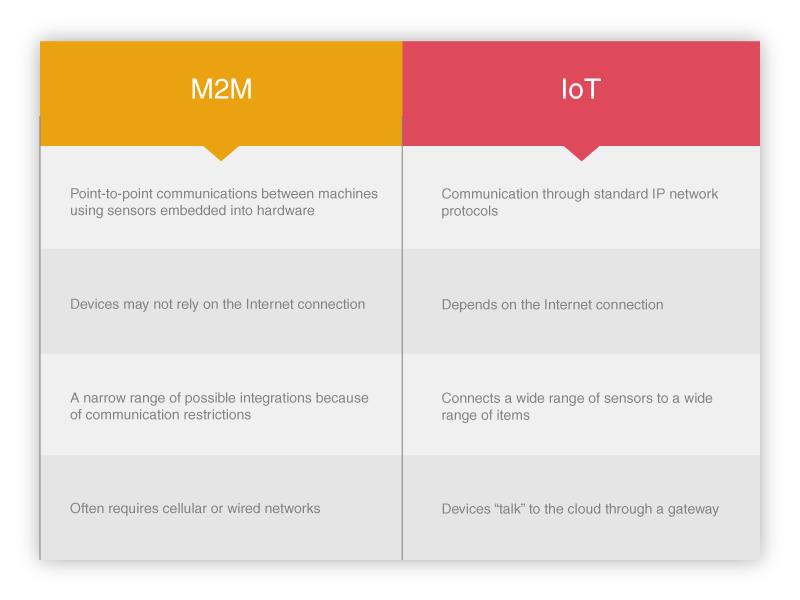

M2M, or machine-to-machine communication, is another popular communication means for automated manufacturing, remote control and supply chain management at the factory. Basically, this technology is considered a predecessor of the Internet of Things and is used at some manufacturing enterprises up to now. However, ever more businesses are replacing into with the IoT infrastructure as an alternative with a lower cost and higher productivity. In order to understand why this is happening, let’s take a look at some core differences between the technologies:

In general, the preference for IoT is preconditioned by better connectivity of devices with a large volume of sensors, solutions, automation and control systems and third-party software applications for data analytics, management and visualization, which brings fruitful business results in the long run.

IIoT: benefits

For many conservative business owners, the concept of Smart Factory sounds like another futuristic buzzword from a sci-fi movie. Although robots and drones are an integral part of the Industrial Internet of Things, the whole idea doesn’t limit itself to self-managed machines and brings obvious advantages. Let’s dig deeper into some of them.

- Better performance

The most of the benefits come from real-time data obtained from connected devices.

Having it online and constantly updated, manufacturers can get actionable insights, such as operational efficiency, off-time consumption or production schedules. This information allows specialists to optimize performance and find opportunities for energy savings. One of the major pitfalls behind performance issues is poor equipment management which has not been properly located, set, or maintained. However, even bigger problem is that such failures often stay unnoticed. With the implementation of IIoT, managers can evaluate similar pieces of machinery in different machines or the location of the equipment to determine what patterns are more effective and how to manage problems with underperforming items.

- Shorter downtime

The logical consequence of performance tracking is getting insightful analytics, which allows predicting equipment failures. Frequency Identification (RFID) tags allow managers to watch manufacturing process from the moment the items appear on the manufacture. Even if some issues emerge, sensors will send alert to the relevant software and give the opportunity to fix these minor problems on time unless they grow bigger. Thus, IoT helps reduce downtime and avoid complete failures and damage of other equipment.

- Higher product quality

The primary goal for manufacturing company is to produce quality products and improve them over time. Even more, some quality issues have a delayed effect, when one failure may affect the whole consignment of goods resulting in product recalls and damaged reputation.

With the data from sensors and automation tools, manufacturers can benefit from predictive maintenance, which can be scheduled based on the historical data. As a result, it enables the remote management and timely enhancement of the product which leads to targeted personalization, lower waste, customer satisfaction, and higher ROI.

- Lower cost

IIoT implementation can also help avoid additional expenses. With this technology, a factory would have IoT sensors embedded into equipment. At the moment when sensors detect a failure in some of the mechanisms, factory staff would receive a notification. They can stop the process immediately and fix the problem. As a result, no significant delays, no detachment recalls and no financial losses.

Challenges to meet

As you can see, IIoT-enabled factory transform the way you manage manufacturing business. However, before starting to make your enterprise smart, mind these two major challenges: connectivity and data security

Сonnectivity is a primary concern, mainly because of the large scale and different ways to rig machines and connect them to the gateway. Sometimes, you’ll need additional hubs or routers to provide access to all the devices. Moreover, even if you manage to set up the network, here comes the new issue – data security.

The more devices you add to a network – the more data you collect, hence the more cybersecurity risks you get. That’s why it is important to find a balance between building a broad network of smart devices, cybersecurity and data protection.

One of the most popular solutions that meet both challenges is the implementation of fog networks, which allows for IoT data storage, processing and analytics at the edge of the network.

However, upon the transition to Smart Factory, the other challenge may emerge since the different devices may historically have used different protocols for data exchange. In this case, it’s better to use MQTT communication protocol that has become a standard for IIoT due to its lightweight overhead two-byte header, publish/subscribe model, and bi-directional capabilities that require minimal network bandwidth.

Perspectives and predictions

It’s still early days of IIoT in the manufacturing industry, and, unfortunately not so many use cases are published to be analyzed and make predictions. However, it’s evident that technology is gaining its popularity and soon, we’ll see new consumer-centric and data-led products and services. What is more, the new concept of connectivity and actionable data will enable custom manufacturing allowing for producing niche solutions rather than mass products. Also, the level of value chain optimization and automation will increase.

As a result, the new Smart Factory will allow companies to build innovative strategies, directed at better products and happier customers.