Nowadays, Industry 4.0 brings disruptive changes to the production and logistics industries as a result of a growing spread of the Internet of Things and cyber-physical systems.The notion itself includes such innovations as intelligent products and processes, a new-generation integration in the supply chain, and the variety of digital technologies in manufacturing. At the end of the day, these changes help to address customers’ desire for highly customized products – the topic we’ve covered in this article. If these demands are satisfied, this new modus operandi of a business results in an increased competitiveness on the market. In the digital age, the voice of modern customers is louder than ever thanks to the mixture of cloud, mobile and social technologies, and many businesses have quickly adopted that new paradigm.

Across the industries, the advantages of Industry 4.0 are closely associated with the use of enterprise resource planning solutions or, simply put, ERPs. Back in 1990, Gartner came up with the term ERP to reflect the evolution of materials requirements planning (MRP) and manufacturing resource planning (MRP II) as they expanded beyond manufacturing into other units of an enterprise, for instance, finance and HR. During that decade, ERP systems evolved in response to Y2K and the introduction of the Euro.

Let’s dive into Panorma’s Report (2017) on ERP systems and enterprise software:

- 81% of organizations are either in the implementation phase or have already completed the process.

- 14% of businesses are in the process of choosing one.

- 5% are currently upgrading their ERP.

- 16% go to the most common reason for implementing ERP: the replacement of an old ERP or legacy systems.

The implementation of ERP systems pursues two goals simultaneously: it helps companies improve their overall performance and revolutionize a brands’ responsiveness to their customers in an innovative way. Modern ERP systems are able to manage large amounts of both transactional and operational information. This type of information serves as a base for making forecasts on production needs for various periods of time.

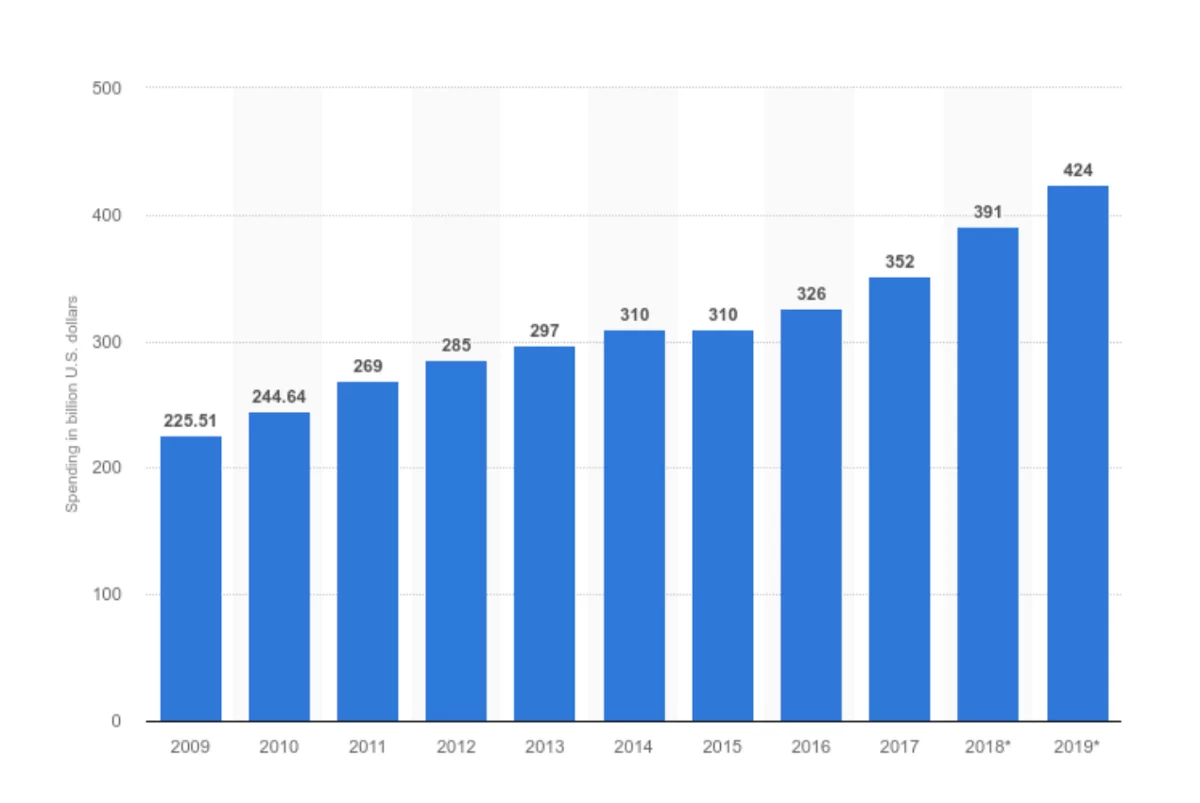

There’s enormous potential for real-time information exchange between the business and the production layers that could increase operational efficiency, allowing organizations to become more flexible and responsive to customized demands. According to the Statista, the global ERP spend has increased by more than 40% in the period of 2010–2017:

In a nutshell, the use of ERPs leads to the following shift in doing business:

- a new level of integration;

- the impulse for enhancements and flexibility;

- the optimization of business processes and corporate strategy;

- improved communications across an organization;

- reduced costs by the elimination of wastes;

However, let’s be fair: a rash implementation of an ERP solution with no clear strategy won’t do a thing. In order to transform a business, one should know how to use it wisely as the key to a proper implementation lies in the deep understanding of core enterprise processes and requirements which would help to identify areas of improvements. The team of colleagues (with an obligatory inclusion of CEOs and top management in it) should think about all essential aspects of running a business: inventory and order management, accounting, human resources and customer relationship management (CRM), and other.

There are four crucial points to consider when implementing a ERP solution:

- The preparation stage demands to design the project scope, objectives, and measurements for the engagement;

- The analysis stage requires a full report on current business processes within an organization and its key performance metrics like productivity, quality, overtime, and inventory;

- The educational stage is all about learning and choosing the best option for a specific company. At this stage, one may resort to the services of experienced ERP consultants;

- Finally – the implementation stage of a chosen concept;

Let’s outline the steps for the last point.

- It all starts with the standardization of business processes and data. One of the biggest advantages of using an ERP system lies the opportunity to make a string of applications use a single definition of data, processing rules and format standards. If you fail at standardization, you will lose to embrace one of the biggest features of a chosen solution, so make sure to make it right.

- The second step is the control of processing. ERP allows users to handily spread up-to-date and accurate data entries (and access to it) within the organization. This way, before getting merged by the system, the data will be processed instantly without human assistance.

- The next step is the use of a system’s workflow capabilities. Most of the ERPs on the market provide the ability to automate processes by passing information from one role to another. Transactions that involve several users can be forwarded in an instant, which significantly speeds up the process of dealing with clients.

- The fourth stage is the integration of the system with customers and suppliers using tools that allow external parties to communicate directly with your ERP while keeping data integrity and security.

- The final chapter analytical tools that define goals within the transaction system and report the current status of completion. Due to the fact that ERPs use a single data model, reporting requires less efforts and provides prompt results.

Conclusion

These are the basic steps to take in consideration when thinking about implementing an ERP system. Sure enough, it’s not an easy task, and companies still face challenges in implementing ERP concepts. After all, it’s much easier to write a blogpost than having the job done as using ERPs goes beyond installing software and following directions in a user manual.

However, a systematic approach to the implementation and focusing on change management will help assure success in the adoption of ERP concepts and the changes required be successful. Maxim Dadychyn, Elinext’s project manager, comments on the situation: “Remote access, flexibility and high-security are the core features to be considered in the development and usage of the ERP system. Today, ERP in cloud with multi-tenant and single-tenant architectures responds to the basic requirements of the global market. And the tendency is that more and more market players make their choice in favor of cloud software. At Elinext, we should apply our experience to propose the appropriate approach to the implementation of ERP solution regarding business strategy and scale of each company.”