From evaluating productivity losses in detail to optimizing maintenance planning, promoting productivity gains, reducing waste, enhancing workplace safety, and more, the promise of AI in manufacturing industry is immense.

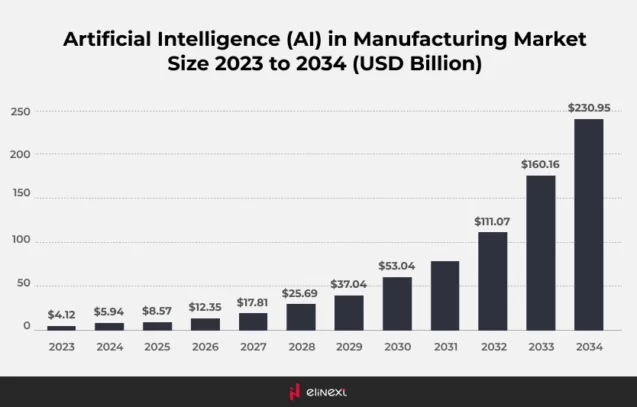

With 68% of manufacturing companies actively implementing AI now, the global artificial intelligence in the manufacturing market is poised for substantial growth – experts predict a dramatic increase from USD 5.94 billion in 2024 to nearly USD 230.95 billion by 2034.

The Importance of AI in Manufacturing Industry Today

In manufacturing, optimization across all business operations is vital. From boosting productivity to maintaining strict quality standards, mitigating compliance risks, and more, achieving these goals today requires leveraging the potential of innovative, AI-enabled solutions.

In fact, companies that rely on AI for manufacturing can outpace competitors by 3.4x.

Implementing AI in Manufacturing Industry

Across different types of manufacturing, AI helps optimize operational processes, reduce production timelines, elevate the quality of products, strengthen system resilience, enhance employee upskilling, and ultimately position enterprises to outperform in an era of digital disruption.

Data Collection and Analysis

Manufacturers own huge volumes of structured (production metrics, maintenance records, logistics, financial data, sales data, HR data, etc.) and unstructured (e.g., free-form text, multimedia files) data. Advanced AI analytics models gather and analyze these troves of data, enabling decision makers to put them to good use.

Integration with Existing Systems

AI manufacturing solutions integrated into existing IT systems (PMSs, computer-aided design software, CRMs, SCMs, EMSs, EHSs, etc.) can streamline designing parts and products, enhance predictive maintenance and quality control operations, support supply chain management and more.

Training and Upskilling Employees

Smarter upskilling and reskilling are one of the major benefits of AI in manufacturing. AI systems evaluate worker performance, identify skill gaps, generate customized training materials, and even embed training directly into workflows, making preparation for new job roles or functions easier.

Data Privacy and Security

Among the notable AI use cases in manufacturing is data privacy and security. Manufacturers use AI to enhance access controls, data encryption and employee training. Moreover, AI-enabled software plays an important role in ensuring privacy compliance with legislation such as GDPR and CCPA, and industry-specific standards like ISO 9001, ISO27001, etc.

Co-develop your groundbreaking manufacturing solutions along with an AI software development services provider that has delivered 70+ AI and 75+ manufacturing software projects.

Taste the power of Industry 4.0 technologies by partnering with an experienced AI integration services provider having 27+ years of IT experience.

What are the Current Trends in AI for Manufacturing?

Applying AI in manufacturing industry improves almost all aspects of production processes, enabling more intelligent, more efficient operations. These seven big AI trends are set to reshape manufacturing in 2025 and beyond.

Generative AI Solutions

From product design and development to predictive maintenance, assembly and quality checks, production planning and more, generative AI is becoming a strategic tool for world-leading conglomerates like Airbus, Siemens, Samsung, etc., operating in the harsh realities of today’s manufacturing.

Predictive Maintenance Solutions

AI-led software analyzes data generated by industrial robotics and automation sensors, IoT sensors, digital twins, as well as human input from machine tools and connected systems, helping manufacturers foresee potential equipment failures and perform timely, targeted maintenance.

AR/VR Solutions

One of the prominent AI for manufacturing trends in 2025 is the rise of AI-driven AR/VR solutions. Enabling smarter, more responsive environments with more immersive visual and auditory elements, these solutions are increasingly used for design & prototyping, equipment visualization, assembly line optimization, and real-time employee instruction.

Blockchain Integration Solutions

As an expert provider of generative AI development services with 10+ relevant completed projects, we are witnessing a growing demand for AI-powered blockchain solutions. When unified, AI and blockchain empower manufacturers with smarter and safer systems for compliance tracking, maintenance optimization, and inventory & supply chain management.

Collaborative Robots (Cobots) Solutions

The use of AI in manufacturing industry converts repetitive, dangerous and physically demanding manufacturing tasks into precise, smooth and efficient processes. Whether it is machine tending and monitoring, part handling or quality checks – if accuracy and speed matter, a collaborative AI robot fits right in.

Edge Computing Solutions

Another trending use case of AI in manufacturing industry is Edge AI (the combination of AI and edge computing). By enabling local, real-time data processing and decision-making with minimal reliance on cloud systems, the technology minimizes latency, reduces bandwidth expenses, and enables instant defect detection during production.

Digital Twins Solutions

Currently, AI technology is actively applied to develop digital twins – virtual replicas of processes, production lines, and supply chains. Powered by IoT sensors, PLCs, and AI algorithms, these models continuously update with live data and accurately simulate, analyze, and predict real-time performance, enabling remote monitoring and optimization.

Empowering Industry 4.0 and Smart Factories with AI

Technological transformation known as Industry 4.0, is reshaping manufacturing, integrating AI, Data science, IoT, AR/VR, Blockchain, and Big Data into smart factories that learn, adapt, and optimize autonomously.

Global companies leading the charge in smart factories, including Bosch, Schneider Electric, Siemens, and Samsung, among others, leverage AI for manufacturing to enhance productivity, predict maintenance schedules, reduce material losses, as well as improve delivery lead times and sustainability across the value chain.

Being an expert in digital transformations with proven expertise in delivering manufacturing software development services (75+ projects) and AI-related software services, including ML software development services (75+ projects), chatbots development services (15+ projects), LLM development services (10+ projects), and ChatGPT development services (10+ projects), Elinext knows what does it takes from manufacturer to capture the potential of AI deployments.

And we stand ready to support them every step of the way, from developing a clear vision of their smart manufacturing initiatives to defining a digital transformation roadmap, building and implementing the required software, and supporting their IT infrastructure that will change and grow.

Elinext expert

Wherever you are on your digital manufacturing transformation journey, the Elinext team is willing and ready to help.

How Elinext’s AI Solutions Help the Manufacturing Industry

Armed with 27+ years of delivering custom manufacturing software development services, Elinext provides top-quality, secure and future-ready solutions powered with advanced techs like AI, Cloud computing, Big Data, AR/VR, Image analysis, etc,, that support both small and enterprise-grade manufacturers with facility management, production flow monitoring, inventory management, and quality control.

Not sure how to get started with Industry 4.0? Let us help.

The Future of AI in Manufacturing Industry

The industry players are increasingly deploying AI for manufacturing to achieve unprecedented operational efficiencies and competitive differentiation. Current AI use cases in manufacturing demonstrate transformative potential across core functions, particularly in predictive maintenance, quality assurance, design optimization, and supply chain resilience.

Looking ahead, organizations are anticipated to embrace and integrate an ‘AI-first’ mindset, catalyzing the development of smarter automation, smarter supply chains, and sound sustainability initiatives in manufacturing.

Conclusion

In the face of rising economic uncertainty, AI use cases in manufacturing – from predictive maintenance to workforce upskilling, digital twins and more – help companies optimize productivity, reduce downtime, deliver improvements to cost and quality, enhance decision-making, and foster Industry 4.0 advancements.

As adoption accelerates, forward-thinking manufacturers should embrace the “AI first” culture to realize the full potential of the opportunities the technology can bring.

FAQ

What is generative AI in manufacturing?

Generative AI in manufacturing refers to the use of a system of algorithms to autonomously optimize designs, predict maintenance needs, simulate production processes, and optimize inventory levels and supply chains.

What are the concerns about AI in manufacturing?

Key concerns about AI in manufacturing industry include high implementation costs, data security risks, data quality, skill shortages, and resistance from employees. Ensuring reliability, ethical use, and seamless human-AI collaboration remain critical challenges.

Should the manufacturing industry leverage AI technology?

Undoubtedly. Manufacturers should implement AI to boost efficiency, reduce the number of products with defects, cut costs, minimize the amount of waste they produce and innovate more quickly and efficiently.

What are the benefits of using AI in manufacturing?

The benefits of AI in manufacturing include minimized downtimes, improved quality control, optimized production costs, enhancements to safety, more resilient supply chains, and environmental sustainability.

What is a smart factory, and how does AI contribute to it?

The smart factory is a network of computing and physical systems within a manufacturing facility that uses artificial intelligence, machine learning, IIoT and other advanced technologies to increase the efficiency of traditional production methods.

What are the challenges of implementing AI in manufacturing?

Implementing AI in manufacturing faces challenges like high initial costs, integration with legacy systems and data privacy concerns. Workforce resistance, skill gaps, and ensuring accurate AI insights and predictions also pose hurdles.