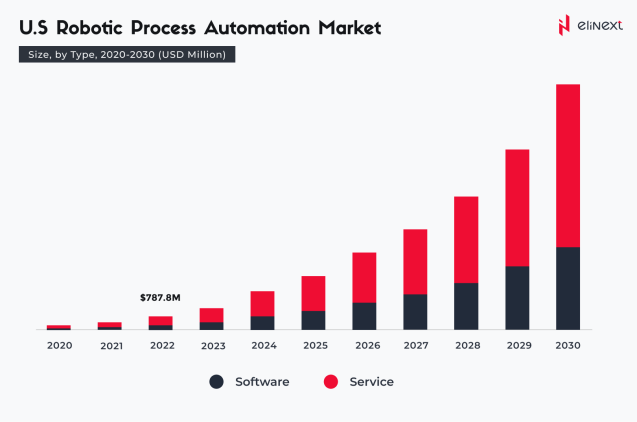

In 2026, more manufacturers are turning to RPA (Robotic Process Automation) to operate faster and more efficiently. The U.S. RPA market is growing rapidly, as businesses are leveraging automation to handle everyday tasks and take advantage of the increased efficiency. Services currently generate the largest share, while software adoption accelerates at a great speed.

Key Takeaways

- The RPA market is expected to reach $28.3 billion in 2025 (Precedence Research).

- The market is forecast to grow at a 43.9% CAGR from 2025 to 2030 (Grand View Research).

- 88% of VPs and C-level leaders say AI is essential to successful RPA adoption (Automation Anywhere).

Key RPA in Manufacturing Trends for 2026

In 2026, manufacturers are using RPA to simplify daily operations and reduce manual work. RPA for manufacturing is helping teams move faster, avoid errors, and stay competitive in a rapidly changing market.

Procurement Management

RPA in manufacturing automates supplier onboarding, purchase orders, and approvals. It reduces manual follow-ups, speeds up sourcing cycles, and ensures procurement teams have accurate data to negotiate better terms.

Inventory Management

Automation helps track stock levels in real time, update systems automatically, and trigger reorders when needed. This reduces stockouts and improves visibility across warehouses and production units.

Accounting Optimization

RPA for manufacturing streamlines invoicing, payment processing, and reconciliations. By handling repetitive finance tasks, it reduces errors and speeds up the month-end close.

Bill of Materials Management

RPA keeps bills of materials accurate by syncing data across systems. It helps update component changes quickly, reduces version errors, and ensures production teams always work with the latest information.

Customer Relationship Management

Automation updates customer records, tracks interactions, and manages follow-ups. This improves response times, gets rid of manual data entry, and helps sales and support teams deliver more consistent customer experiences.

Order Management

RPA manages order entry, validation, and status updates across systems. It minimizes processing errors, shortens order cycles, and allows customers to receive accurate delivery and pricing information.

Freight Management

Automation supports shipment scheduling, carrier selection, and tracking updates. It helps cut delays and logistics costs, as well as improve coordination between manufacturing, warehouses, and transport partners.

Performance & Compliance Reporting

RPA collects data from multiple systems to generate accurate reports. It supports compliance needs, reduces manual effort, and gives leaders timely insights into operational performance.

Data Management

RPA improves data quality by automating data entry, validation, and migration. It decreases inconsistencies between systems and offers clean, up-to-date information for manufacturers’ decisions.

“RPA will soon be a key driver of workforce transformation in manufacturing, not just efficiency. Companies are already combining RPA with machine learning to predict equipment failures and reassign skilled workers to other tasks. RPA will create a safer, more adaptive production environment for all of us.” ― Marek Novak, Senior Automation Analyst

What are the Benefits of RPA in Manufacturing Operations

RPA is transforming manufacturing by mainly handling repetitive tasks. This frees skilled teams to focus on high-value work instead, as well as delivers a range of other benefits. Here are just some of the benefits of RPA in manufacturing:

Improved Operational Reliability

Automation ensures processes run consistently and accurately, reducing human errors. By handling repetitive tasks like data entry, production monitoring, and order processing, RPA helps operations stay reliable.

Stronger Decision Confidence

RPA collects and consolidates data across systems in real time. This improves decision-making, enabling faster responses to production issues, inventory gaps, and supply chain challenges.

Improved Compliance Posture

Automation keeps records complete and up to date, making audits and regulatory reporting easier. RPA enforces standardized processes, reducing compliance risks and helping manufacturers meet quality and safety standards.

Better Use of Skilled Teams

By offloading repetitive tasks, RPA allows engineers, planners, and operators to focus on innovation, problem-solving, and process improvement. This maximizes the value of skilled workers and drives continuous improvement.

Predictable Scalability Without Process Redesign

RPA can scale up operations quickly without changing core processes. Whether production volumes increase or new product lines are added, automation adapts.

Lower Operational Friction Across Functions

Automation smooths handoffs between departments, reduces delays, and ensures consistent information flow. RPA connects procurement, inventory, production, and finance, making the entire operation more coordinated.

Start Your RPA Transformation Today

Elinext PRA Solutions for the Manufacturing Industry

Elinext delivers tailored RPA solutions for manufacturers. We combine custom RPA development services with manufacturing software development services to optimize workflows and reduce costs. As an AI software development company, it’s our passion to integrate intelligent automation and improve your business.

What are the Best RPA Platforms for Manufacturing

Choosing the right RPA platform is key for manufacturers looking to automate processes efficiently. The top platforms combine ease of use, scalability, and integration capabilities to streamline operations and maximize ROI.

UiPath

UiPath offers a user-friendly interface and extensive automation tools. It supports workflow automation, data extraction, and system integration, which makes it ideal for manufacturing.

Microsoft Power Automate

Microsoft Power Automate integrates seamlessly with Microsoft 365 and other enterprise systems. Manufacturers can automate repetitive tasks, connect multiple applications, and gain real-time insights.

SS&C BluePrism

BluePrism provides enterprise-grade automation with strong security and governance features. Its digital workforce can handle high-volume, repetitive tasks across manufacturing operations.

Automation Anywhere

Automation Anywhere combines RPA with AI-powered analytics, enabling intelligent process automation for manufacturers. It supports everything from invoice processing to supply chain management.

Unlock Your Manufacturing Potential with RPA

The Future Trends in RPA for Manufacturing

The future of RPA for manufacturing points to smarter, more connected operations. Companies are combining RPA with AI and IoT to predict equipment failures, optimize supply chains, and enable real-time decision-making. As automation evolves, manufacturers will see faster production, fewer errors, and more flexible, data-driven processes shaping the factories of 2026 and beyond.

Conclusion

RPA is a vital strategic advantage in manufacturing. With RPA in manufacturing, businesses can boost efficiency, reduce costs, and empower skilled teams. Companies embracing RPA today are better positioned to innovate, scale, and remain competitive in the fast-evolving industrial landscape.

FAQ

Why is RPA becoming important in manufacturing in 2026?

RPA for manufacturing boosts efficiency, reduces errors, and helps manufacturers manage complex operations faster.

What are some practical use cases of RPA in manufacturing?

Use cases of RPA in manufacturing include inventory tracking, procurement, invoice processing, order management, quality checks, and supply chain monitoring.

How does RPA interact with other automation technologies?

RPA works with AI, IoT, and ERP systems to automate tasks, analyze data, and optimize processes across production and logistics.

Does RPA replace manufacturing workers?

No, RPA in manufacturing only handles repetitive tasks, freeing employees to focus on higher-value work like innovation, planning, and problem-solving.