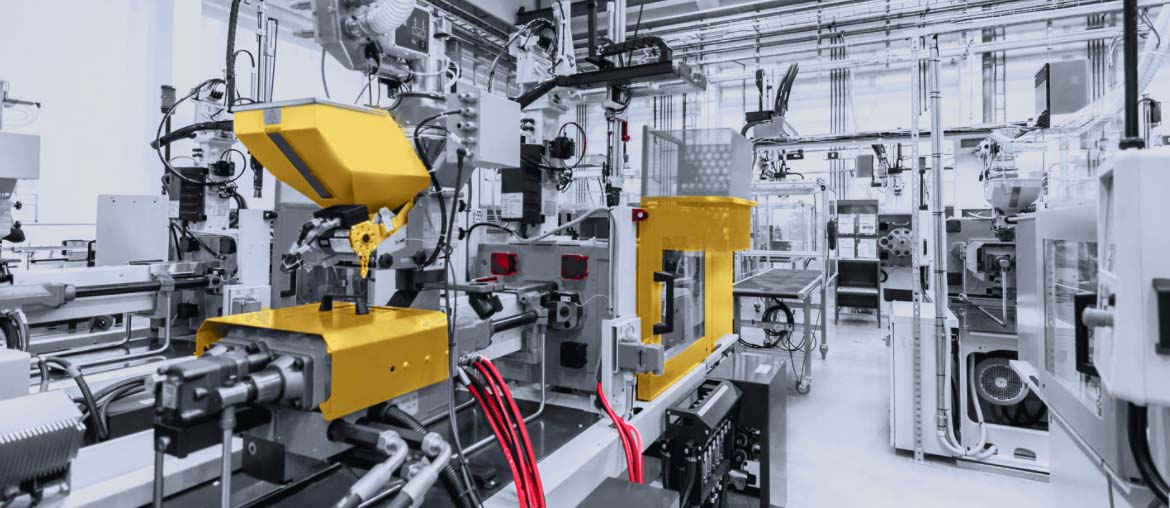

Smart Manufacturing

Solutions

Elinext: Leading in Smart

Manufacturing Services

Manufacturing Services

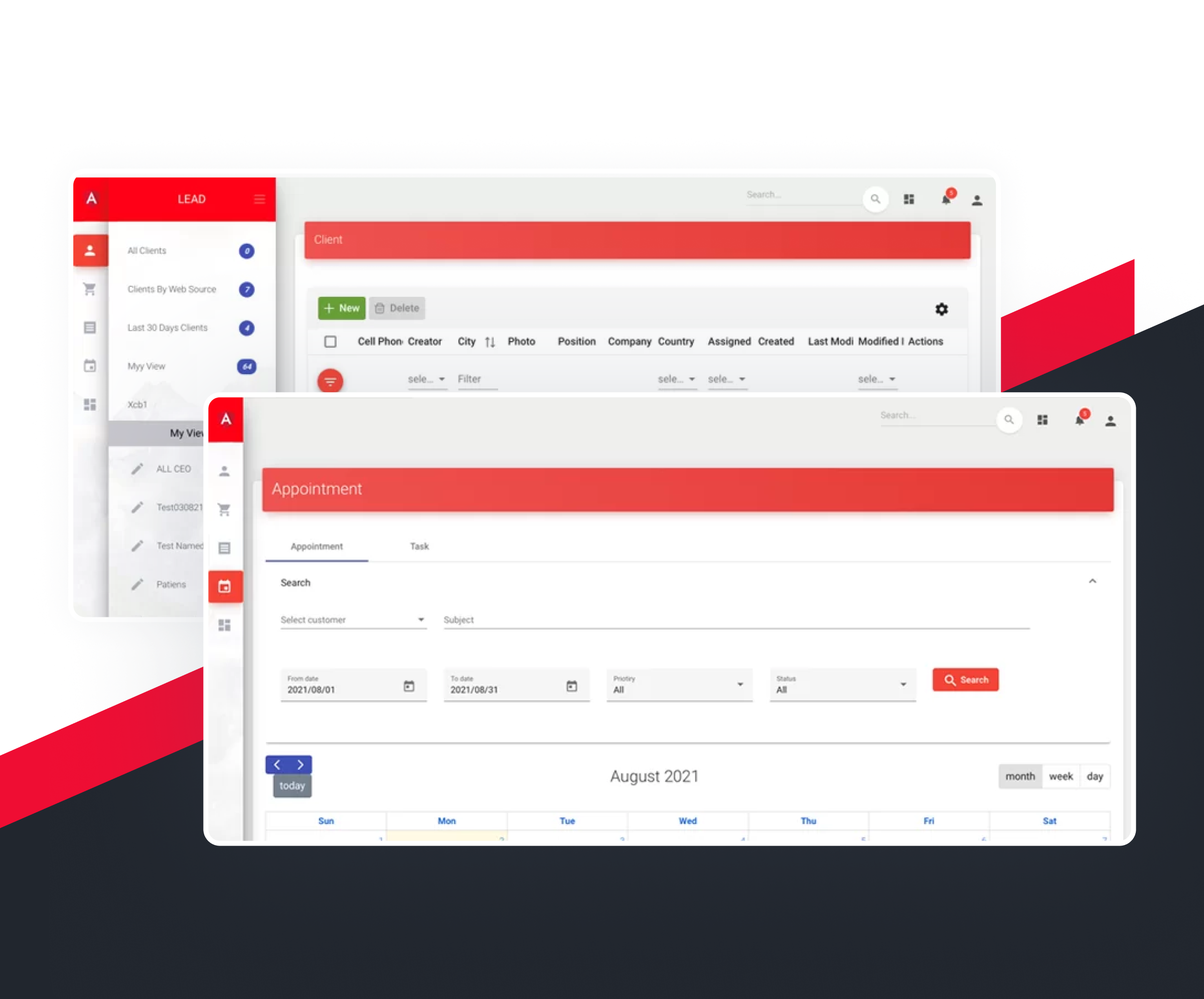

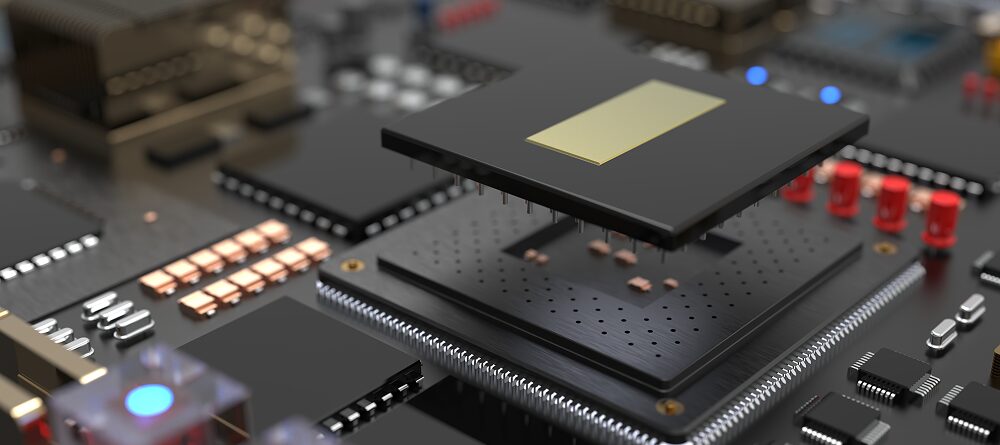

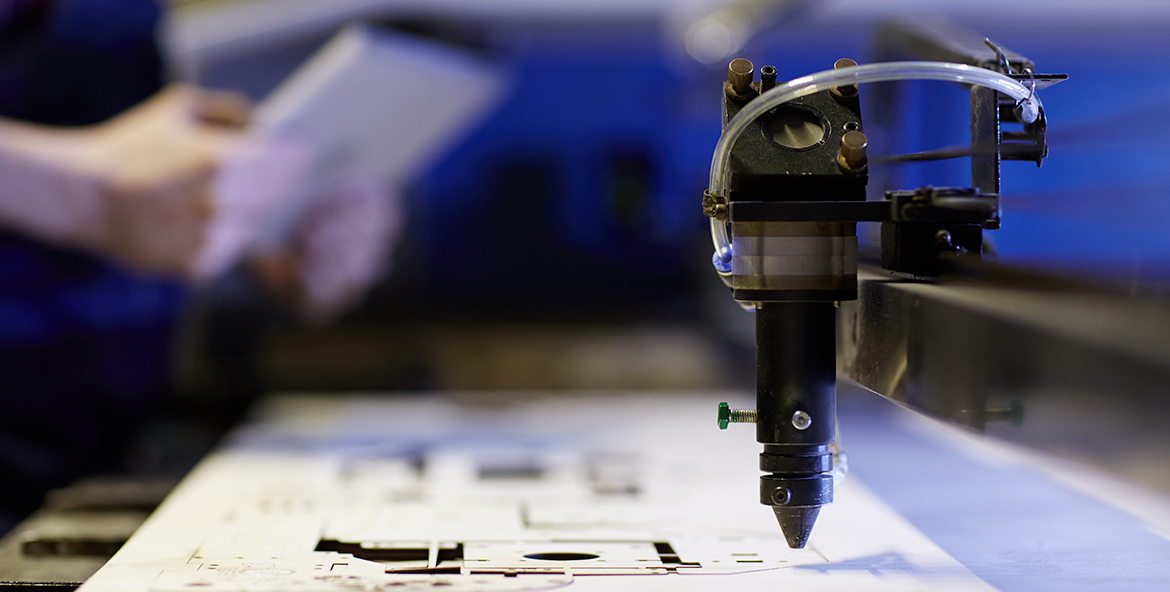

Elinext provides custom smart manufacturing solutions that help businesses automate workflows, enhance production visibility, and reduce operational costs. Our multidisciplinary teams turn complex manufacturing needs into scalable, user-friendly systems. ideal for companies without internal IT departments. We ensure seamless integration, fast deployment, and measurable results.

Elinext provides custom smart manufacturing solutions that help businesses automate workflows, enhance production visibility, and reduce operational costs. Our multidisciplinary teams turn complex manufacturing needs into scalable, user-friendly systems. ideal for companies without internal IT departments. We ensure seamless integration, fast deployment, and measurable results.

Custom Smart Manufacturing

Solutions We Offer

-

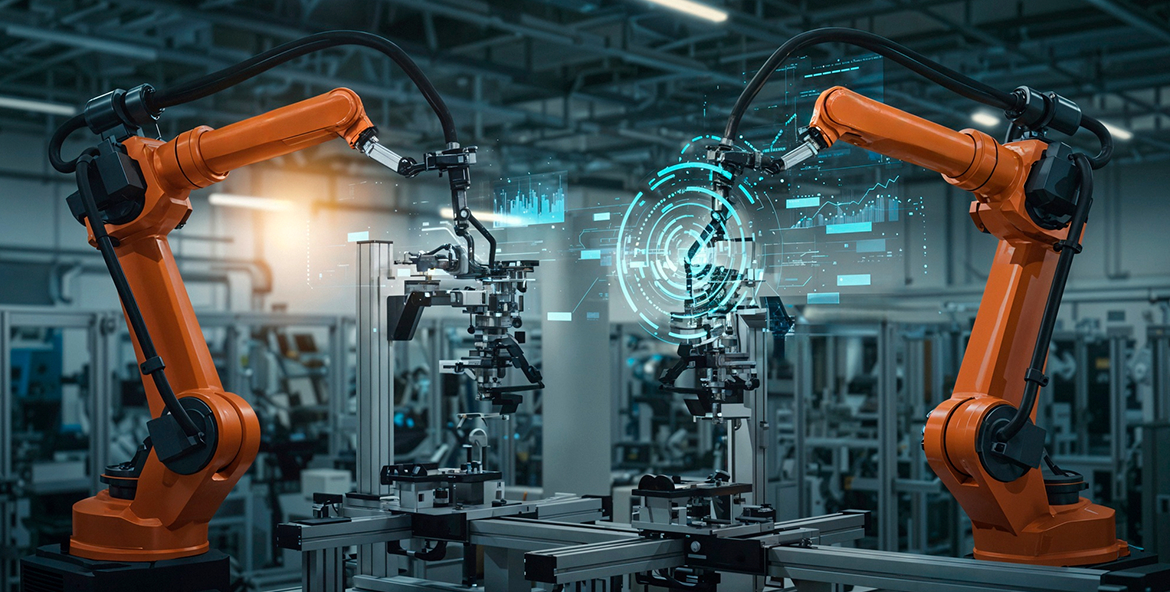

Elinext builds AI and machine learning tools that detect production anomalies, predict maintenance, and optimize resource allocation. These solutions help manufacturers make faster, data-driven decisions while reducing downtime and waste.

-

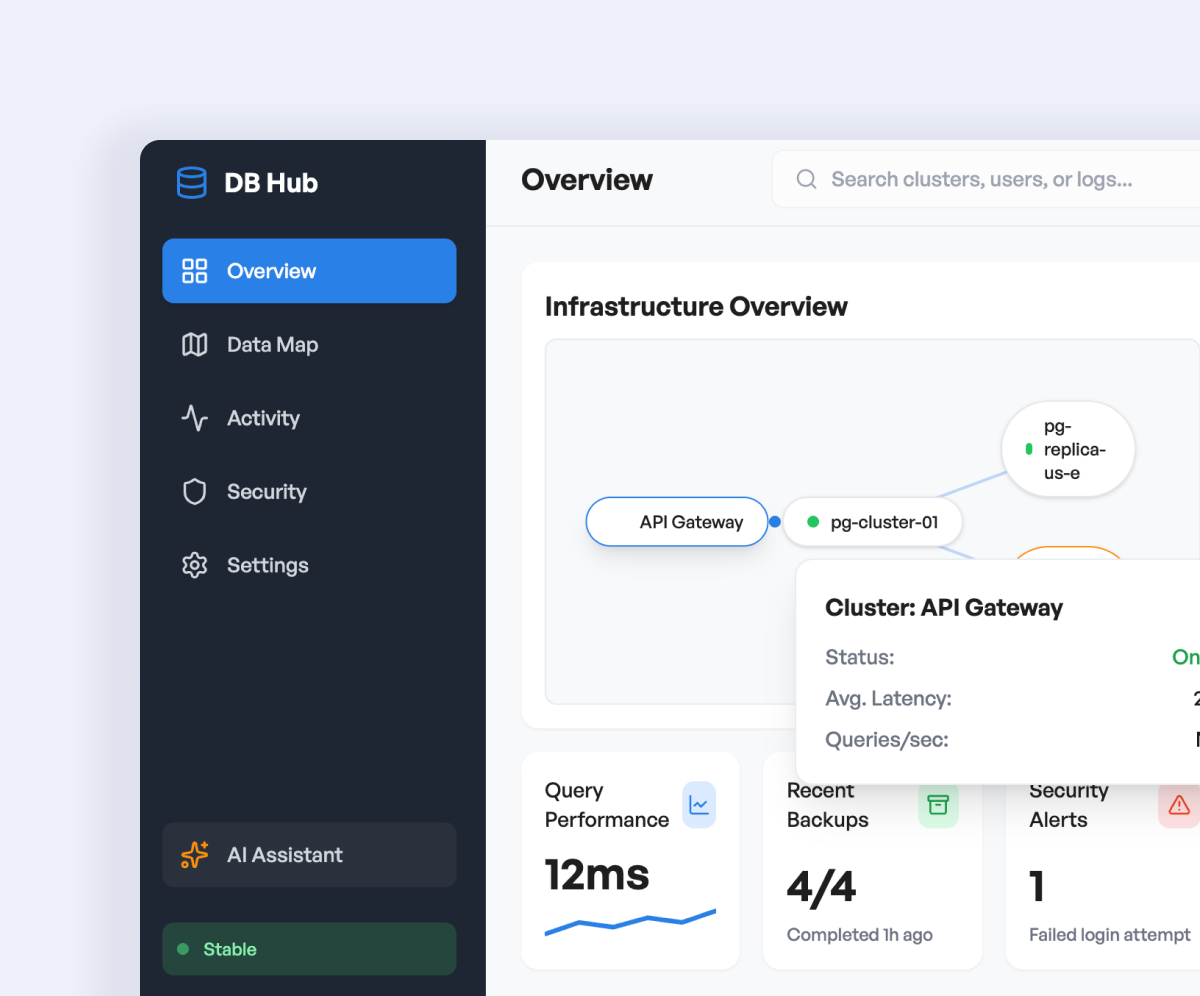

Our IIoT systems connect machines, sensors, and production lines to give you real-time insight and control. Ideal for remote monitoring and predictive maintenance, these tools enhance safety, cut costs, and increase overall equipment effectiveness (OEE).

-

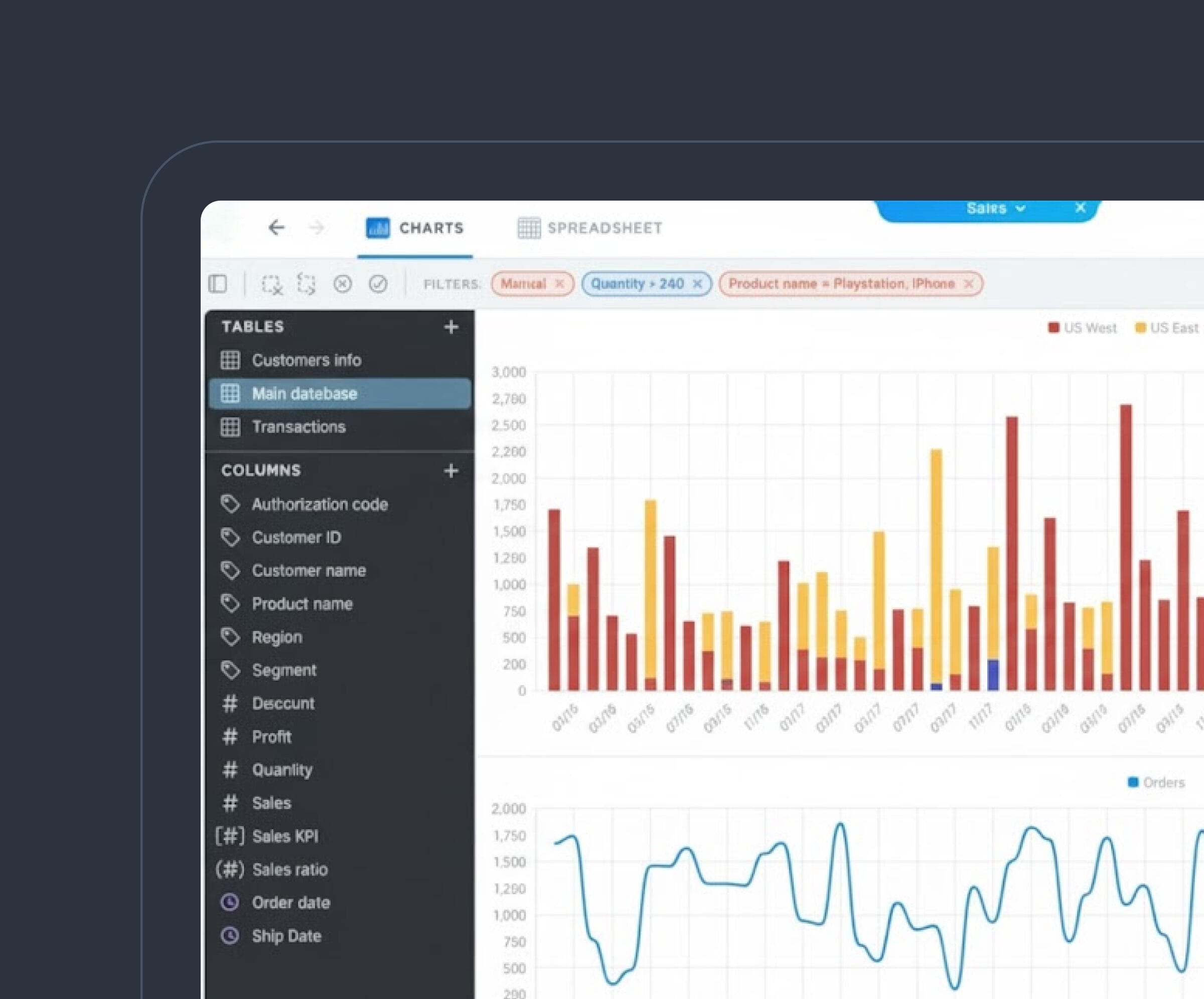

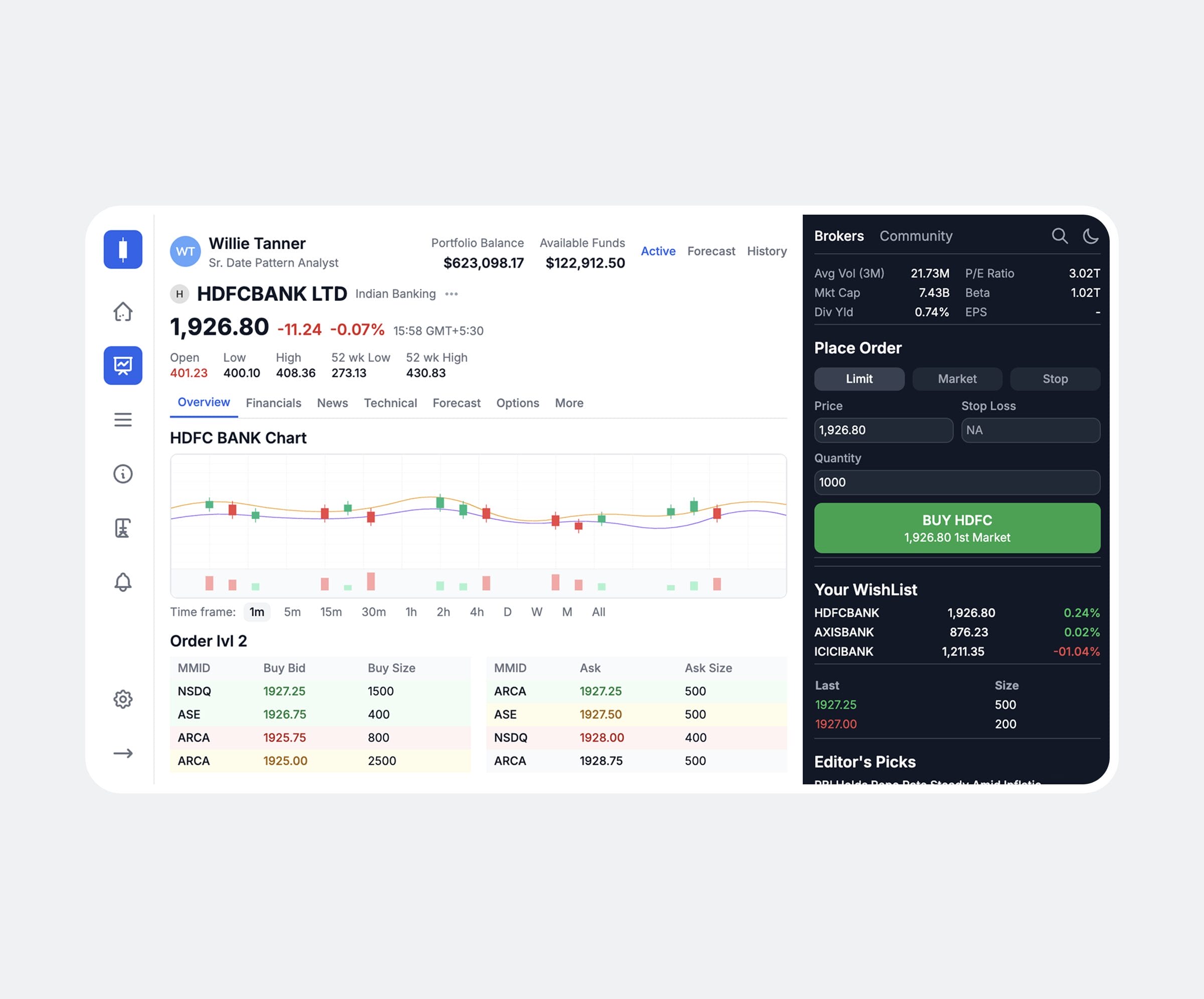

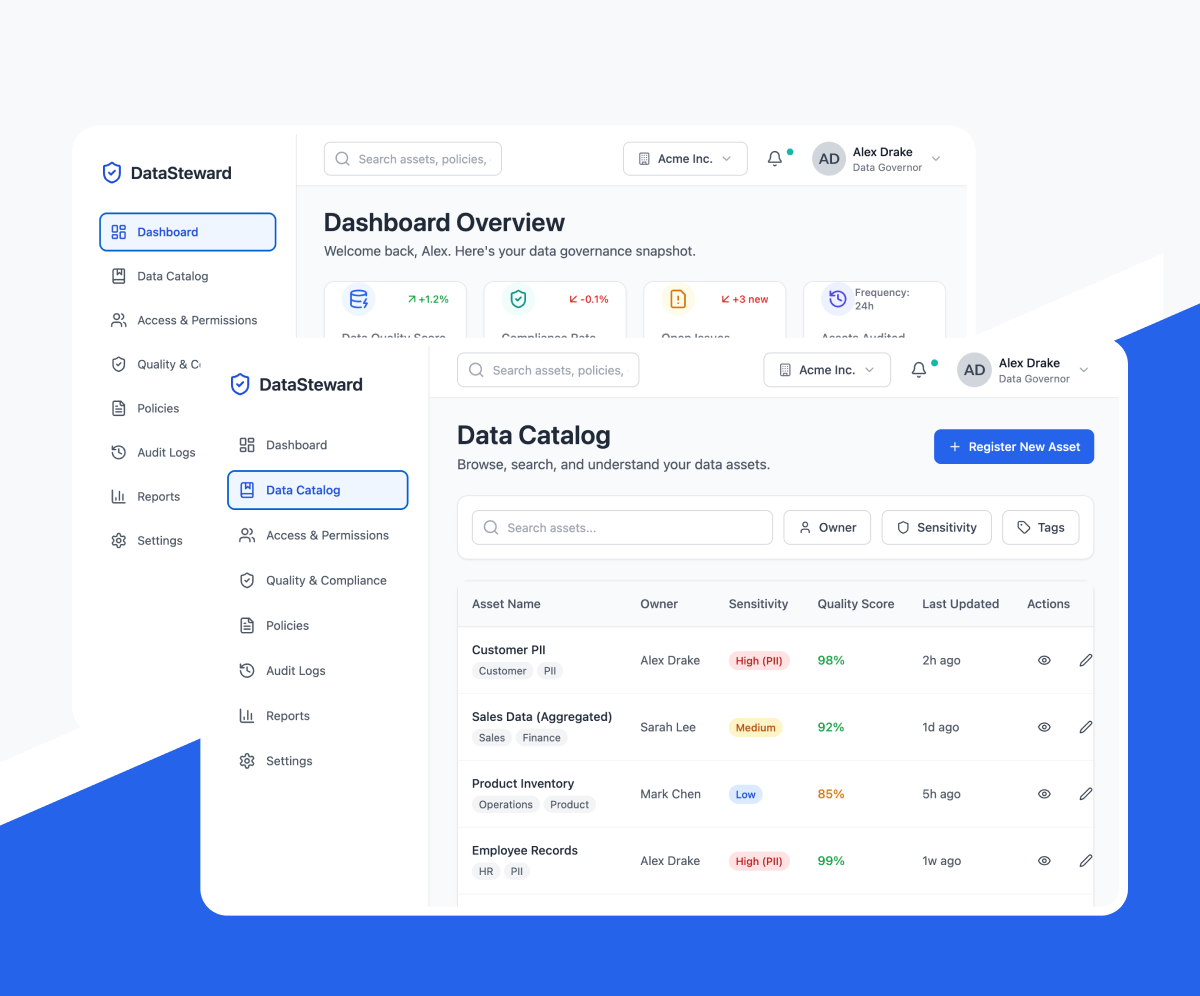

We turn raw industrial data into actionable intelligence. Our big data platforms support real-time analytics, demand forecasting, and quality control, helping your team make smarter decisions and identify hidden opportunities for efficiency.

-

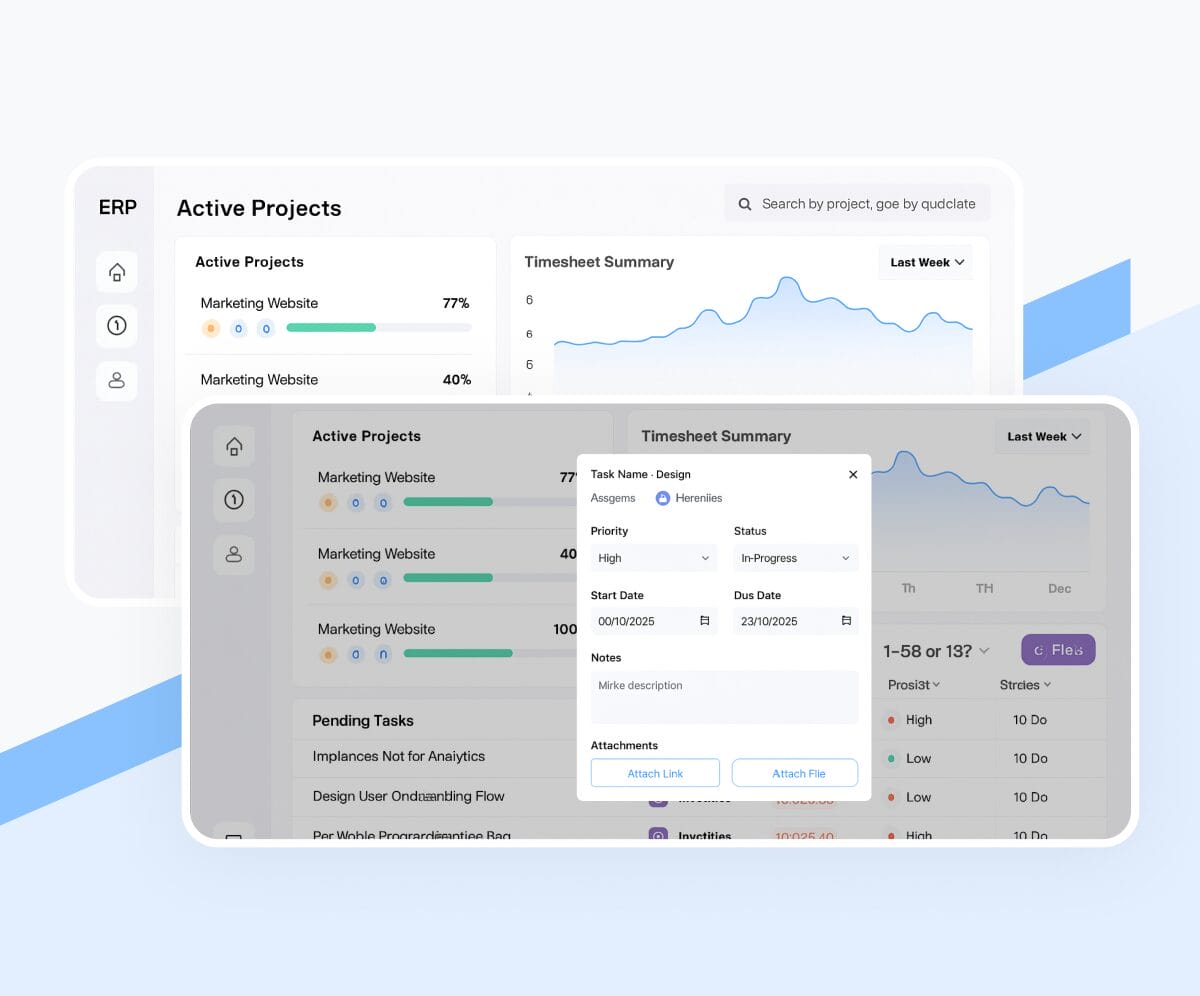

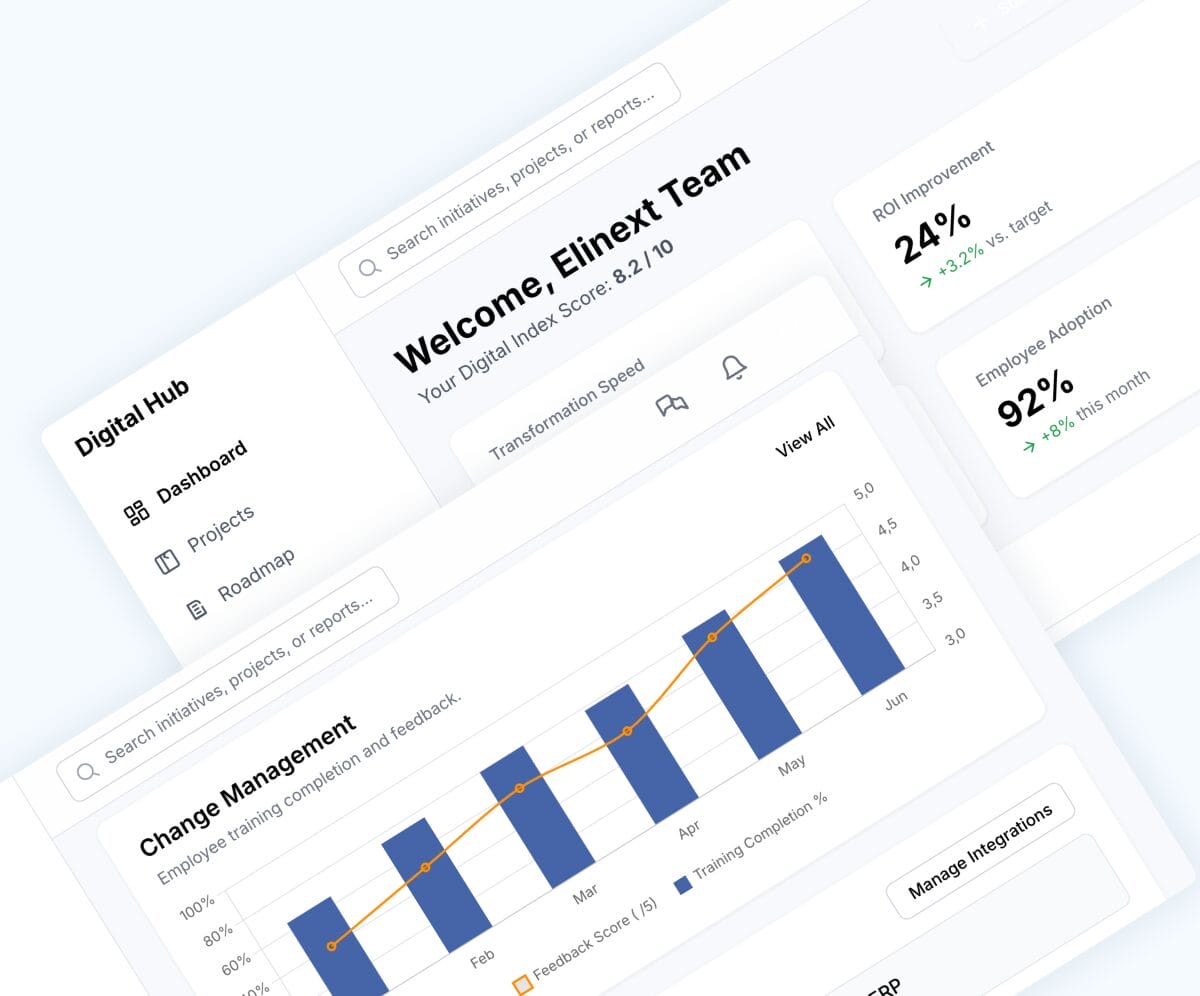

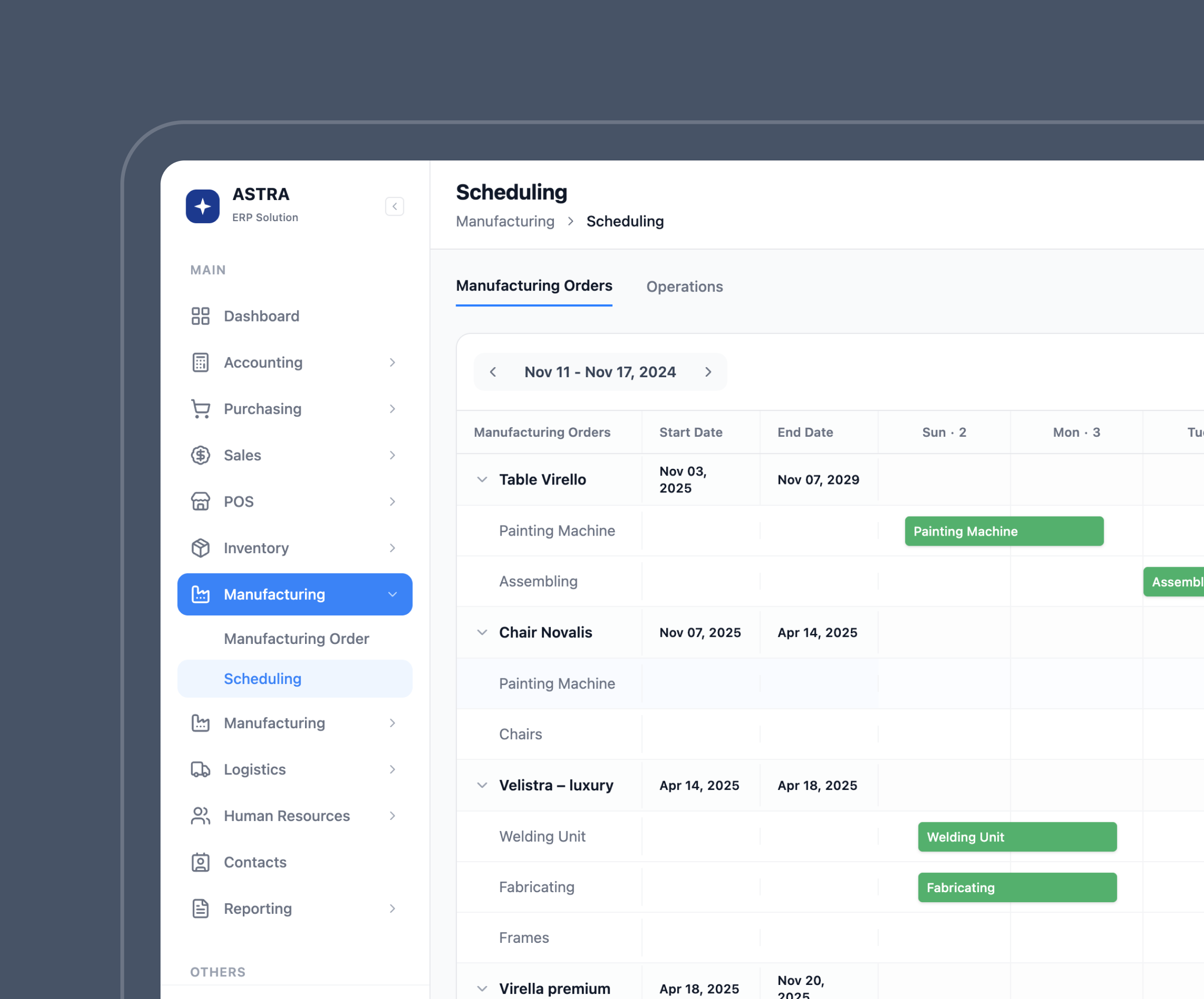

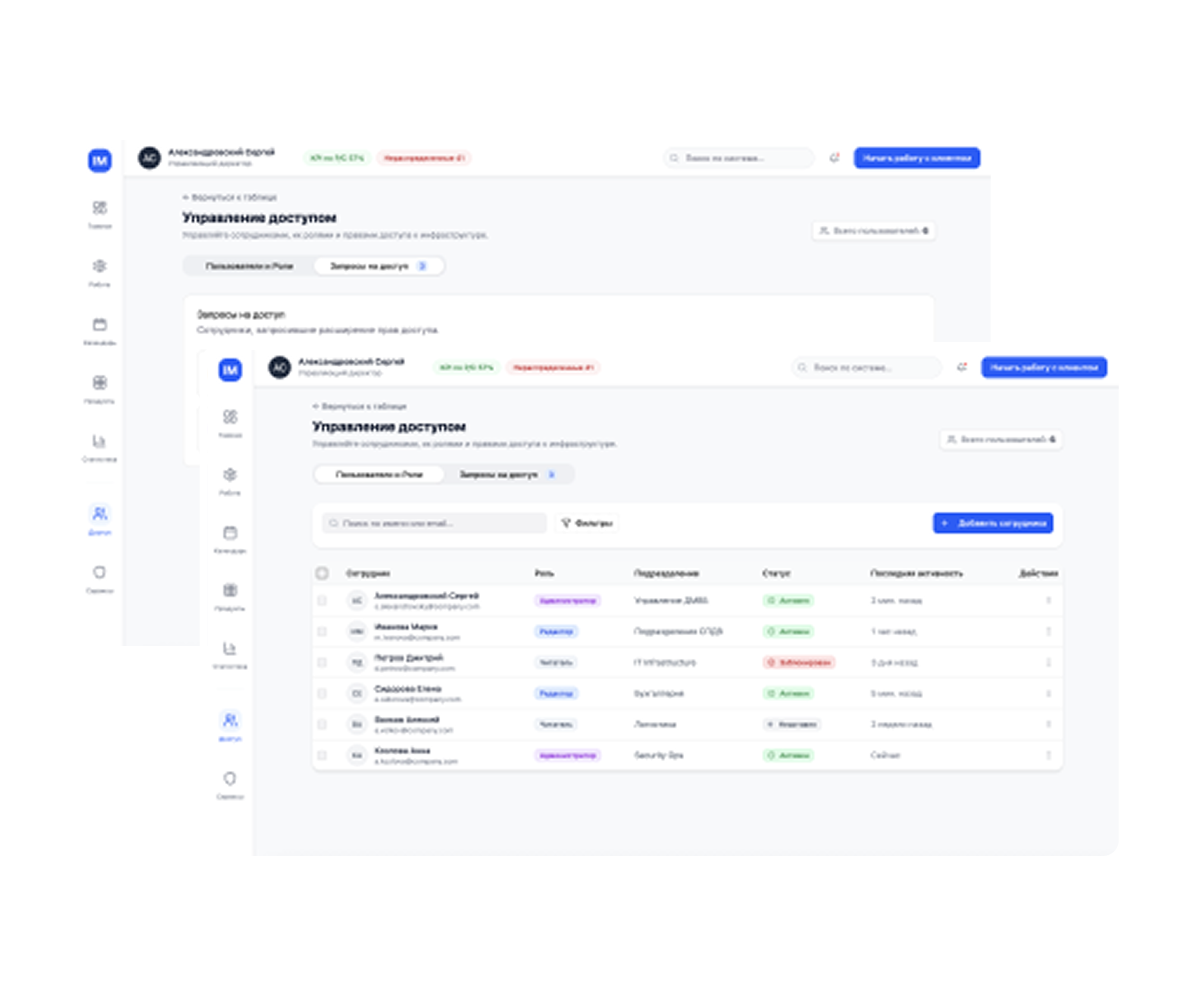

Elinext develops modular ERP systems tailored for manufacturing operations. These systems integrate all key processes – from inventory to finance – into a single platform, increasing transparency, reducing errors, and speeding up delivery cycles.

-

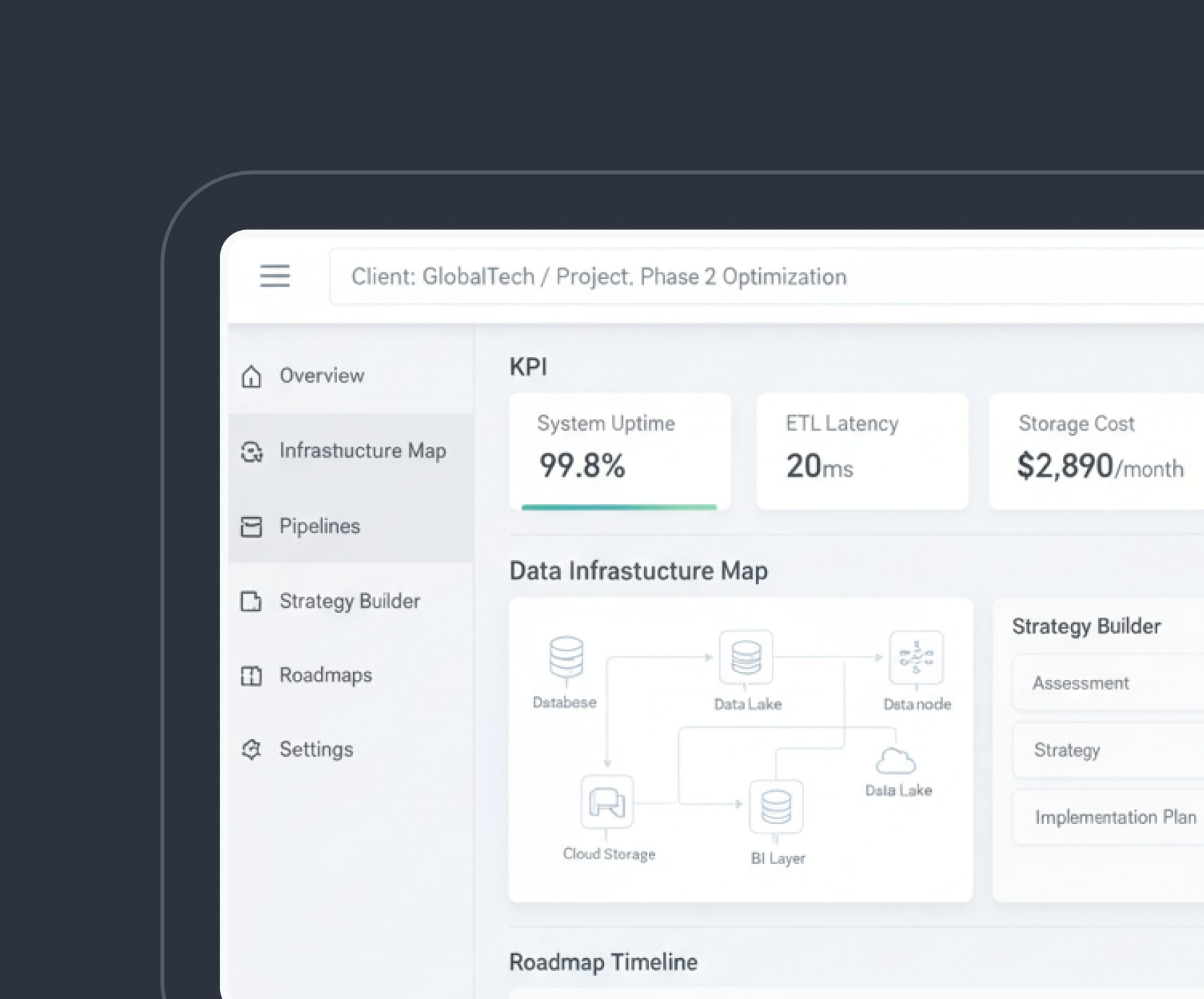

Our business analysis services uncover bottlenecks and opportunities through deep process evaluation. We turn your goals into tech specs, reducing implementation risks and aligning your smart manufacturing roadmap with ROI-focused outcomes.

-

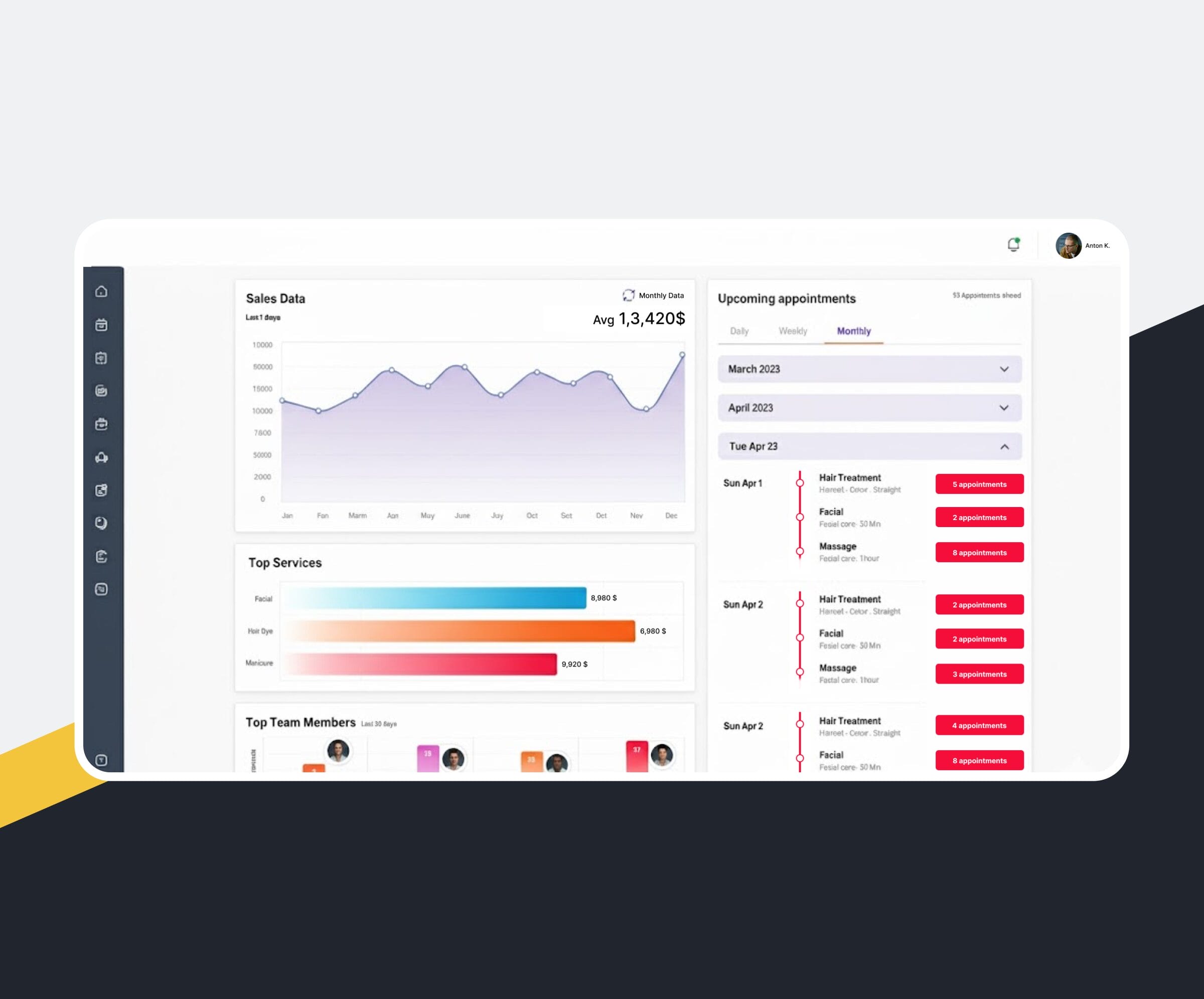

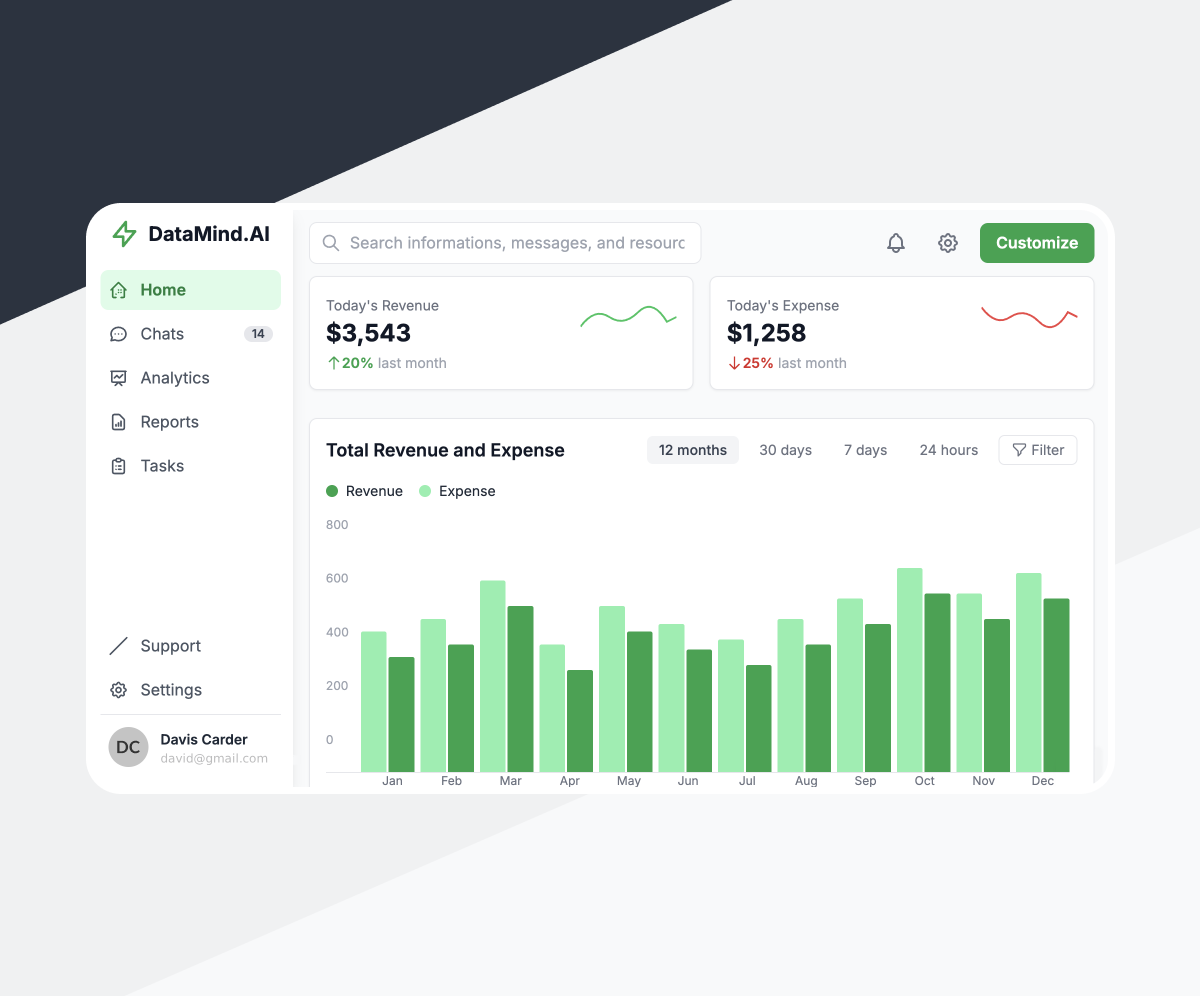

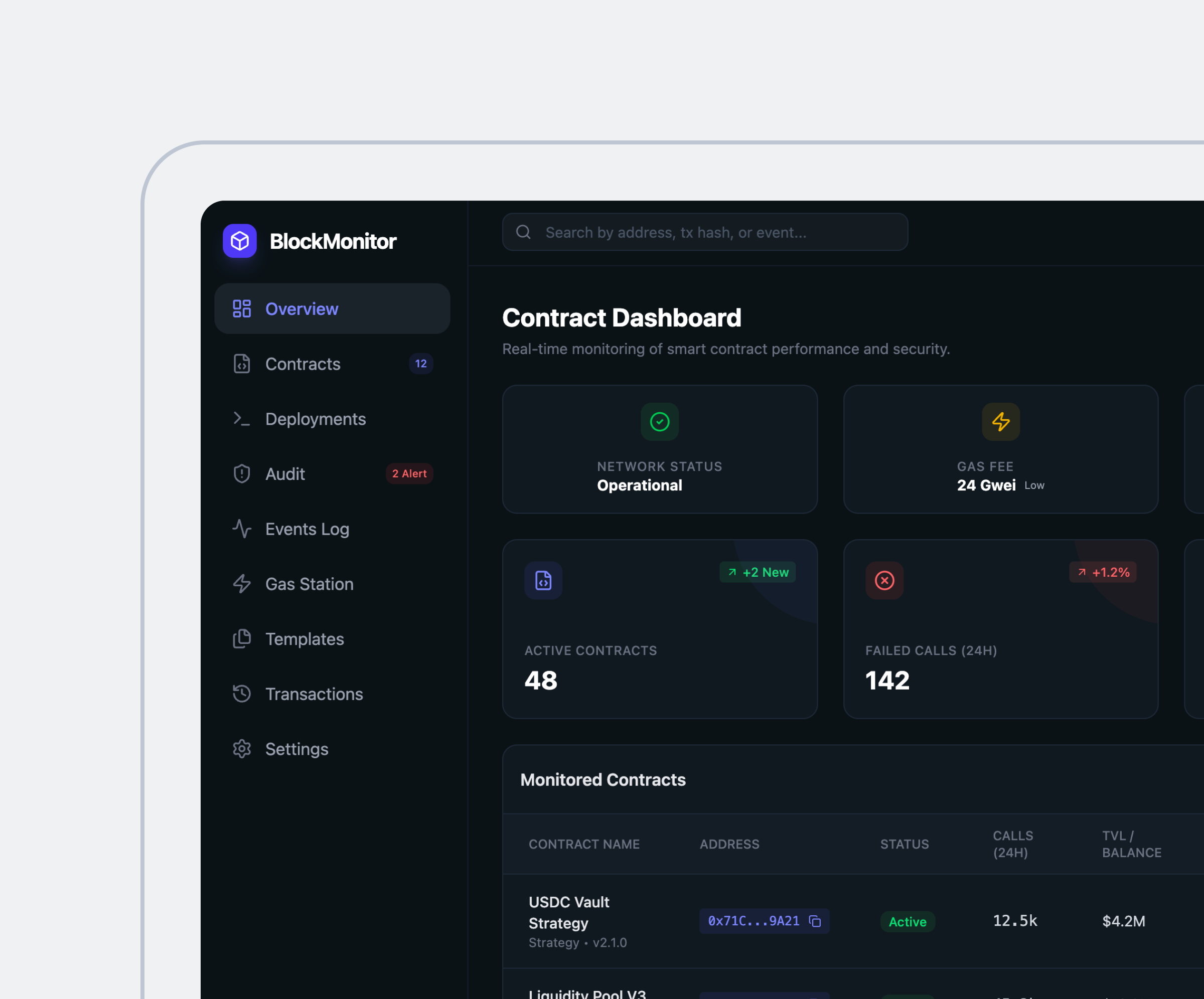

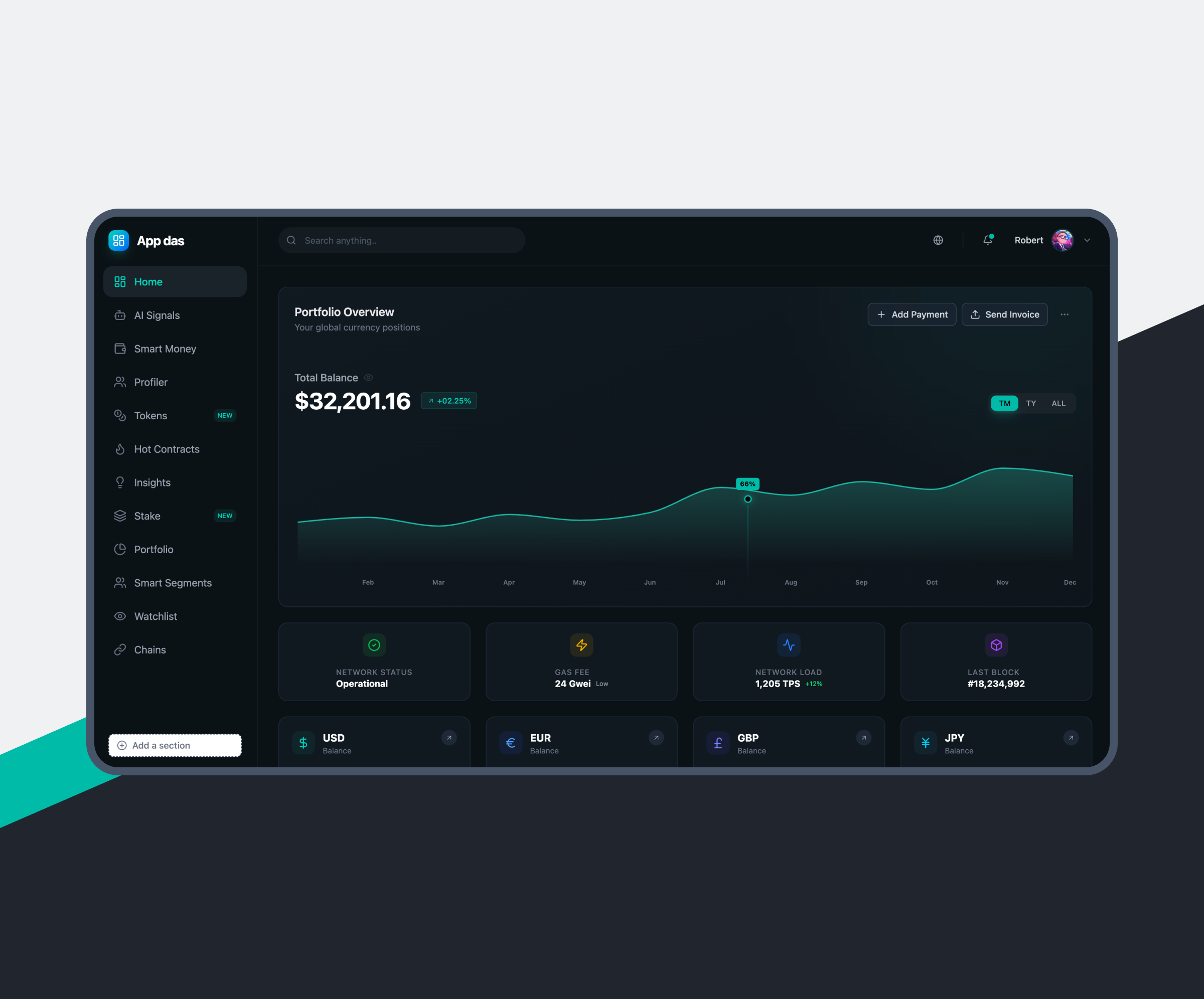

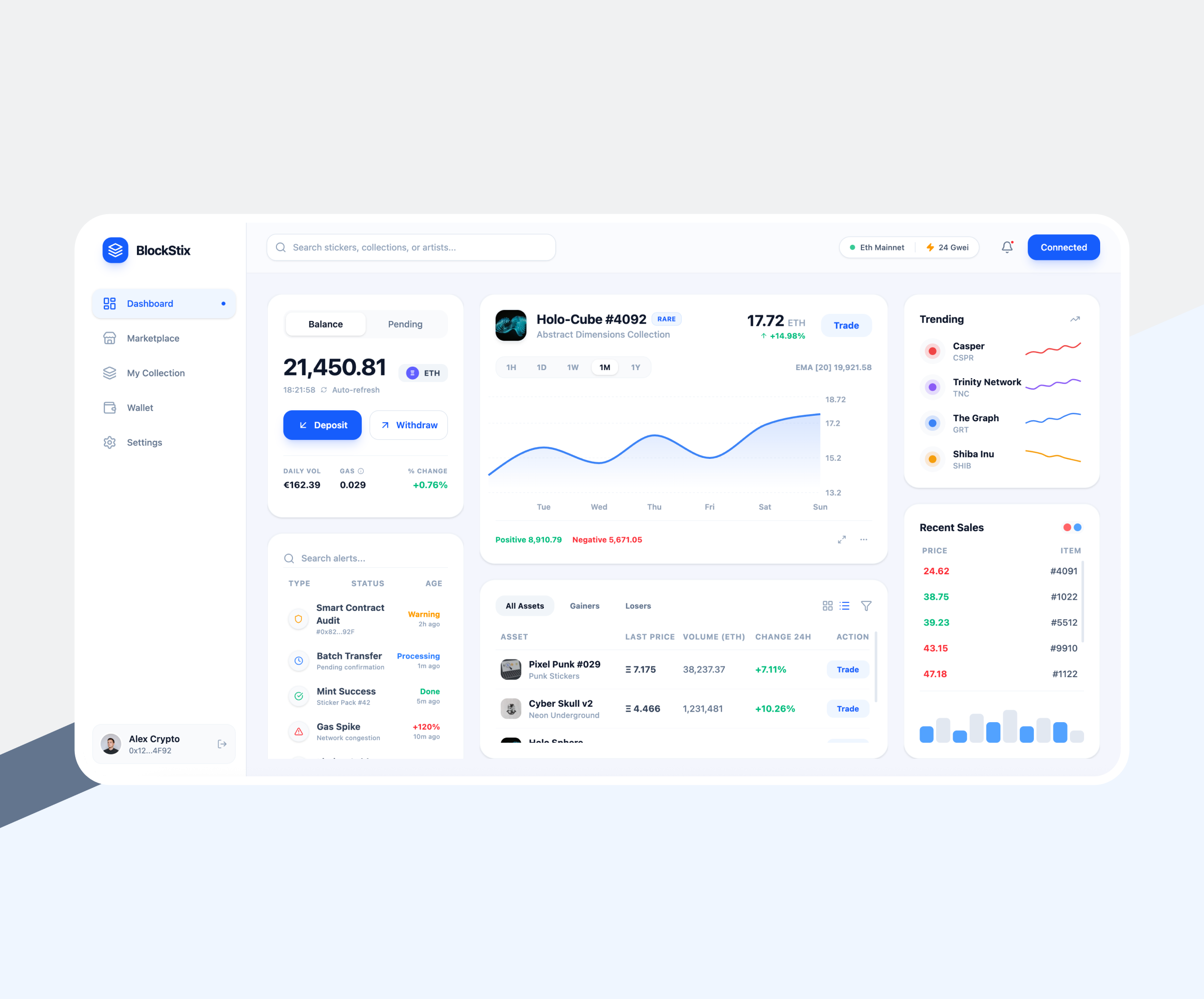

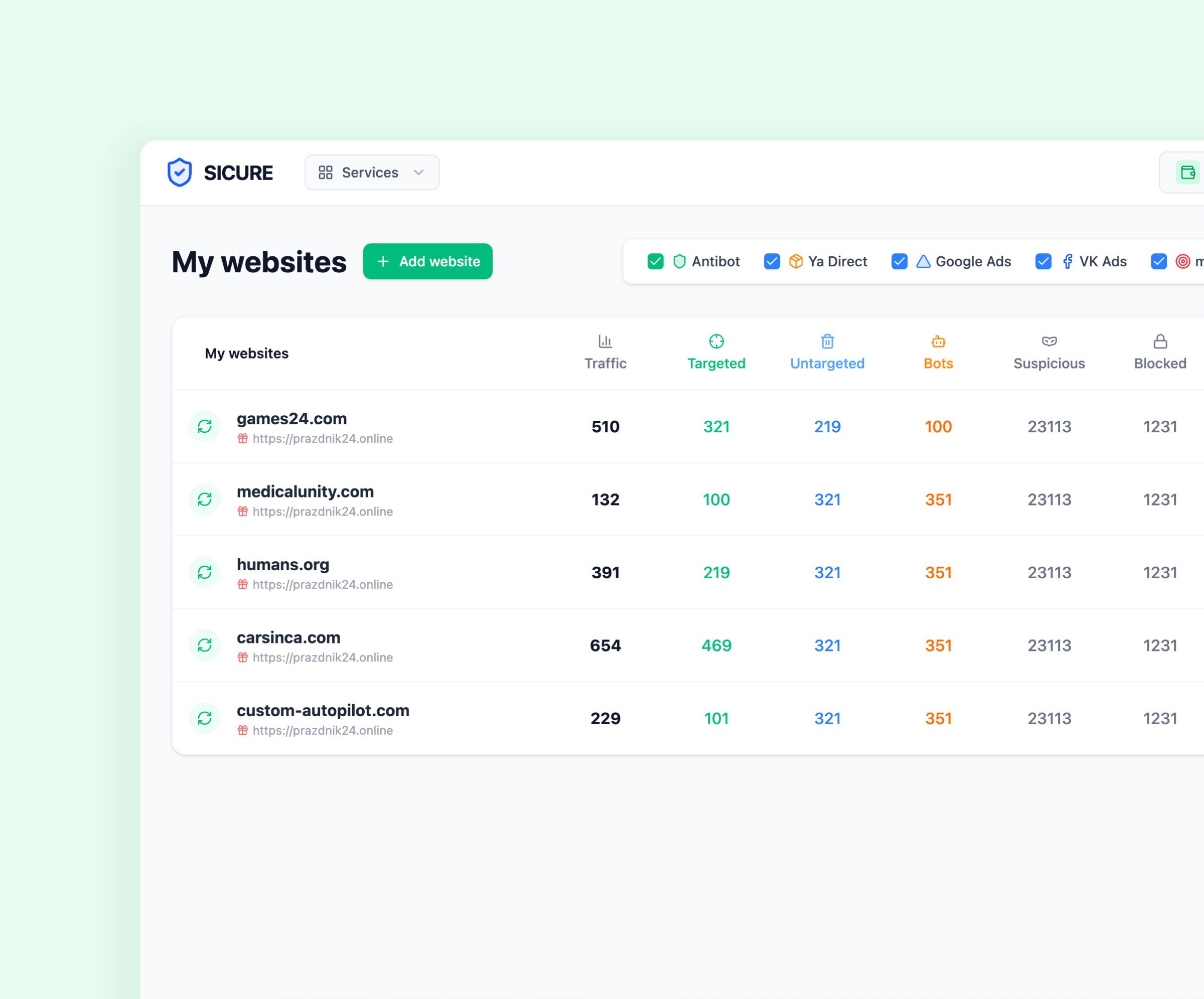

We create smart dashboards and KPIs tailored to your factory floor. With BI tools, manufacturers gain 360° operational visibility, enabling timely interventions, strategic planning, and measurable improvements across every department.

-

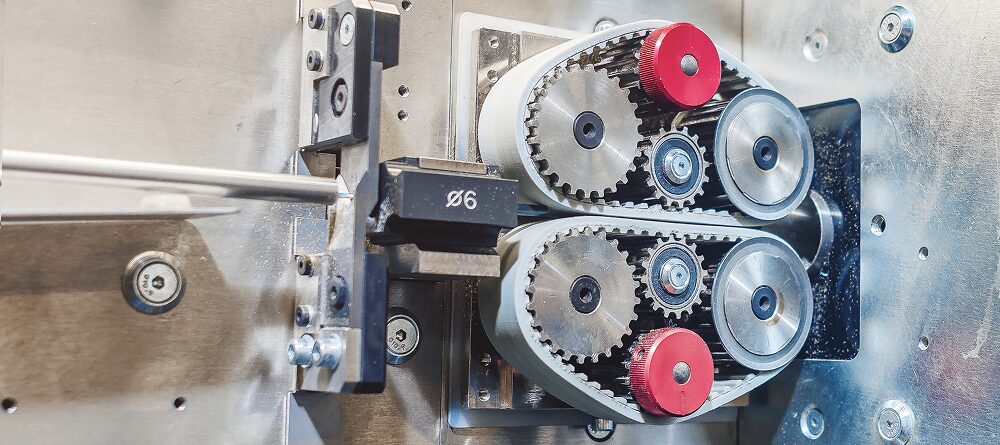

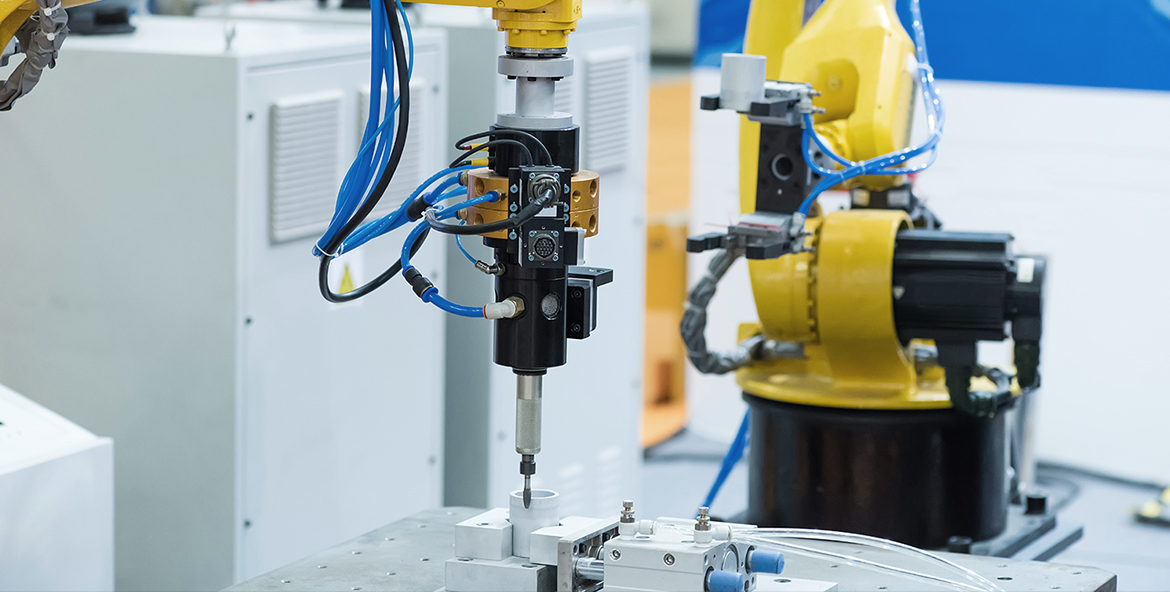

From robotic arms to assembly-line automation, we design and integrate robotics that reduce labor costs and improve production precision. These solutions ensure consistency, improve safety, and boost throughput even with limited human resources.

-

Digital Twins Solutions

Elinext builds digital twins that replicate your physical assets in a virtual environment. This enables simulation, performance testing, and predictive analysis – empowering you to optimize performance and avoid costly downtime.

-

We deliver AR/VR applications for smart training, remote assistance, and design visualization. These immersive tools reduce onboarding time, improve maintenance accuracy, and support efficient collaboration between engineers and technicians.

-

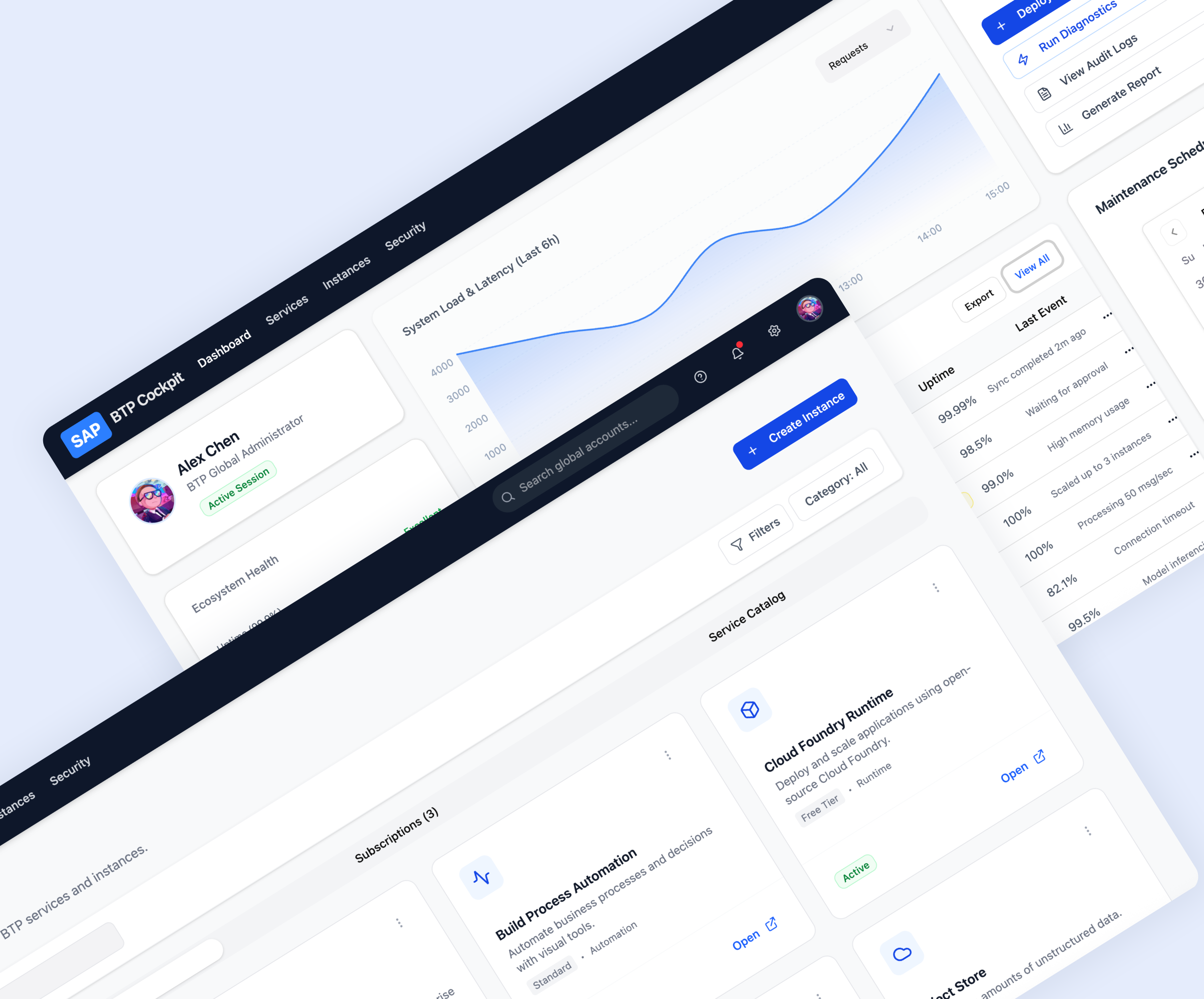

Our cloud platforms enable scalable, secure access to manufacturing data from anywhere. Elinext’s cloud solutions simplify system integration, cut IT overhead, and support faster innovation through centralized control and data sharing.

-

We protect smart manufacturing environments with multi-layered security, from endpoint protection to secure data transmission. Our solutions help prevent IP theft, production disruption, and compliance violations.

Sustainability and ESG Services for the Smart Manufacturing Industry

Sustainability and ESG services are a foundation for embedding sustainability into smart manufacturing ecosystems. The service is intended for Industry 4.0 enterprises and digital factories. The result is transparent resource management and ESG governance. Elinext delivers smart manufacturing solutions aligned with ESG strategies.

Our Awards and Recognitions

Why Choose Elinext As A Smart Manufacturing

Software Development Company

Clients We Serve

The Benefits Of Smart Manufacturing

Solutions By Elinext

Choose Your

Service Option

Hire Smart Manufacturing Developers

from Elinext

Why Elinext?

Listen to Our Clients

FAQ

-

Smart manufacturing is the use of digital technologies, like IoT, AI, and automation, to optimize factory operations, improve product quality, and increase agility across the entire production lifecycle.

-

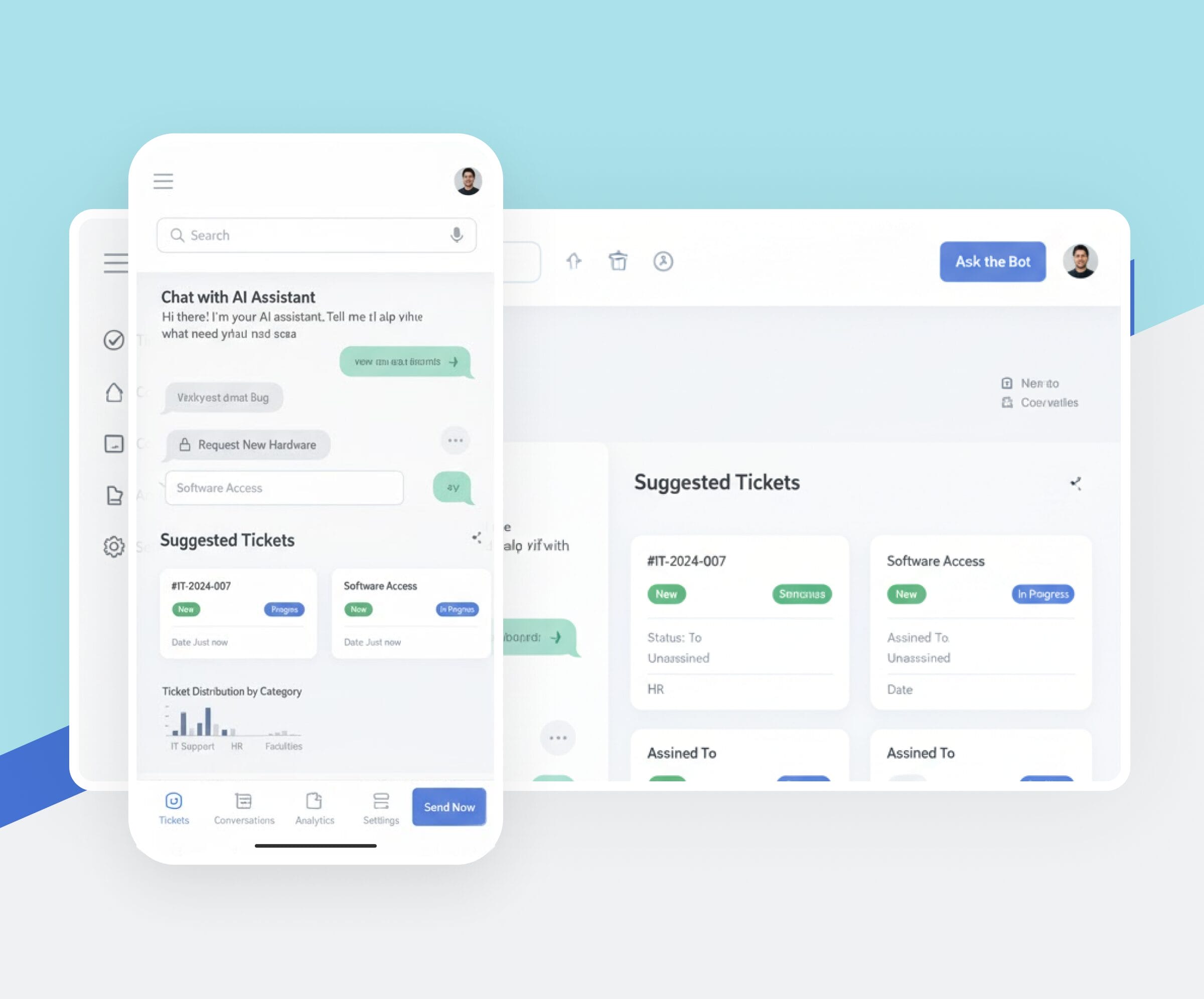

Smart manufacturing services include building integrated software and hardware systems that automate, monitor, and analyze industrial processes in real time, enabling better decision-making, predictive maintenance, and operational efficiency.

-

They reduce downtime, boost productivity, and lower operational costs. With real-time data and automation, businesses improve quality control, scale faster, and respond more effectively to market demands.

-

Smart manufacturing shifts repetitive tasks to machines, allowing employees to focus on higher-value roles. It increases workplace safety, creates demand for tech-savvy skills, and encourages continuous learning.

-

Industry 4.0 is the broader concept of the fourth industrial revolution, while smart manufacturing refers to its practical implementation, applying digital technologies to real-world factory operations.

Looking for Related Services?

Smart Manufacturing Solutions

ArticlesSmart Manufacturing Solutions

Articles

Articles

Articles